Choosing a cutting mat is not simply about protecting a work surface. In professional environments, it is about accuracy, safety, consistency and long-term value. Whether in manufacturing, engineering, education or specialist workshops, the cutting mat becomes part of the workflow itself.

This is where the Rhino difference is clear.

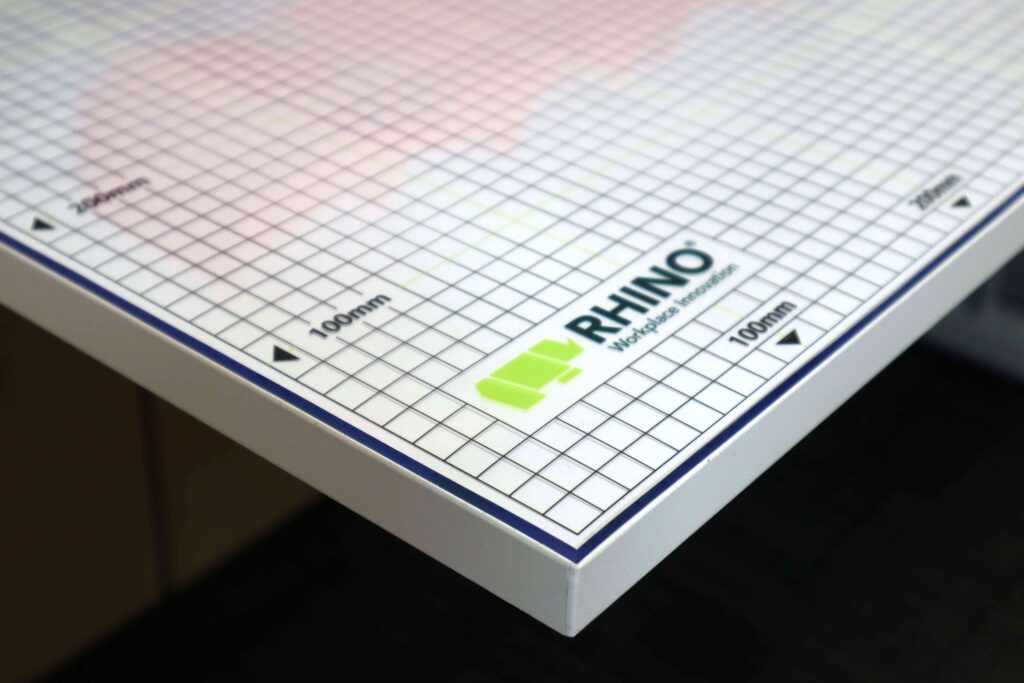

Rhino cutting mats are designed for organisations that need more than a basic consumable. They are engineered working surfaces, trusted in demanding environments where precision, durability and repeatability matter. This article explains what genuinely sets Rhino cutting mats apart, and why so many organisations across the UK continue to specify them.

Built for Professional Environments, Not Light Use

Many cutting mats on the market are designed for light, occasional use. When placed into busy workshops, production areas or shared environments, their limitations quickly become apparent.

Rhino cutting mats are developed specifically for professional, high-use settings. They are designed to perform under repetitive cutting, heavier tools, longer shifts and shared workstations. From the outset, the focus is on maintaining a stable, consistent cutting surface that supports accuracy while protecting tools and workbenches.

This approach means Rhino mats are not treated as disposable items. They are designed as long-term assets, supporting productivity while reducing replacement frequency and disruption.

Self-Healing Performance That Delivers Consistency

A self-healing cutting mat should do more than recover visually. It should continue to perform accurately over time.

Rhino self-healing cutting mats are manufactured using carefully selected materials and layered construction. This allows cut lines to close effectively, helping the surface retain its integrity even under sustained use. The result is cleaner cuts, improved accuracy and reduced blade wear.

In high-precision environments, including advanced manufacturing and elite motorsport engineering, Rhino’s cutting mats are used during component preparation, composite trimming and rapid prototyping tasks. In these settings, surface consistency is essential. The mat is not a background accessory, but a controlled working surface that supports accuracy and repeatability.

Protecting Tools, Workbenches and Accuracy

A cutting mat should actively protect the assets around it. Poor quality mats often lead to damaged blades, scored benches and inconsistent cutting results.

Rhino cutting mats are engineered to provide the correct balance between surface resilience and blade support. This allows clean cutting without excessive resistance, while preventing damage to the workbench beneath. Over time, this reduces blade replacement, protects high-value work surfaces and maintains a professional working environment.

Many customers report noticeable improvements after switching to Rhino, including better cutting accuracy, fewer damaged tools and cleaner, more controlled workstations.

Consistent Performance Across Sizes and Bespoke Solutions

Inconsistency across different mat sizes is a common issue with lower-grade suppliers. A smaller mat may perform well, while larger formats behave differently under pressure.

Rhino applies the same manufacturing standards across its entire range. Whether specifying a standard size or a bespoke solution, customers receive the same performance, durability and surface finish.

For complex layouts or specialist applications, Rhino also provides custom cutting mats and large-scale rollout programmes. Each solution is assessed based on workspace layout, workflow and handling requirements, ensuring the mat supports the task rather than restricting it.

Performance Over Time, Not Just Purchase Price

Comparing cutting mats on price alone rarely reflects real-world value.

Lower-cost alternatives often show rapid wear, surface grooving and deformation. This leads to inconsistent cutting, increased blade damage and frequent replacement. Rhino cutting mats are designed to maintain performance under sustained use, even in demanding environments.

Customers who move from lower-grade mats frequently highlight improved longevity, cleaner appearance and reduced disruption. Over time, this results in a lower total cost of ownership, rather than a short-term saving.

Trusted in Demanding Sectors

Rhino cutting mats are used across a wide range of sectors, each with its own requirements.

In manufacturing and warehousing, durability and safety are critical. In automotive, aerospace and advanced engineering, precision and contamination control matter most. In education, consistency, visibility and longevity are essential in shared environments.

Rhino designs its cutting mats to meet these varied demands, which is why they are regularly specified for multi-site projects and national rollouts. Their adaptability is a direct result of engineering-led design, not generic specification.

Sustainability Built Into the Product Lifecycle

Sustainability is treated as a core consideration, not an afterthought.

Rhino recognised early that many cutting mats relied on materials that were difficult to recycle. Since then, ongoing efforts have focused on improving material choices, including offering a dedicated mat recycling scheme and moving towards recycled and PVC-free packaging where possible.

By choosing longer-lasting cutting mats that reduce waste and replacement frequency, organisations can support their environmental goals without compromising performance.

Specialist Support and Long-Term Partnership

Another key difference lies in how Rhino works with its customers.

Rather than pushing standard products, Rhino focuses on understanding how cutting mats are actually used. For larger or more complex requirements, on-site discovery visits allow workflows, layouts and usage patterns to be assessed in detail. This ensures that cutting mats are properly specified and integrated into the working environment.

For many customers, this specialist support provides confidence that their cutting solution has been chosen for the right reasons, not simply price or availability.

Why Organisations Choose Rhino Cutting Mats

Rhino does not compete on being the cheapest option. It competes on performance, durability, innovation and decision confidence.

The difference lies in supplying cutting mats that perform consistently, protect valuable assets and stand up to real-world use. It is this approach that has built long-term relationships across manufacturing, engineering, education and specialist industries throughout the UK.

Upgrade to a Cutting Surface That Performs

If your current cutting mats wear out too quickly, damage tools or fail to support your workflow, it may be time to experience the Rhino difference.

Explore the range of premium cutting mats, discuss bespoke solutions with the team or arrange an on-site visit to see how Rhino supports safer, smarter and cleaner workstations.

The right cutting surface is not an accessory. It is an investment in accuracy, safety and long-term performance.