Finding the right CNC machining partner isn’t just a box-ticking exercise it’s an important step in keeping your production running smoothly. The right supplier will help you hit quality standards, stay on schedule and adapt to shifting project demands. The wrong one? That’s when delays, cost overruns and frustrations start creeping in. Here’s what to look for to make sure you’re in safe hands.

What Is CNC Machining?

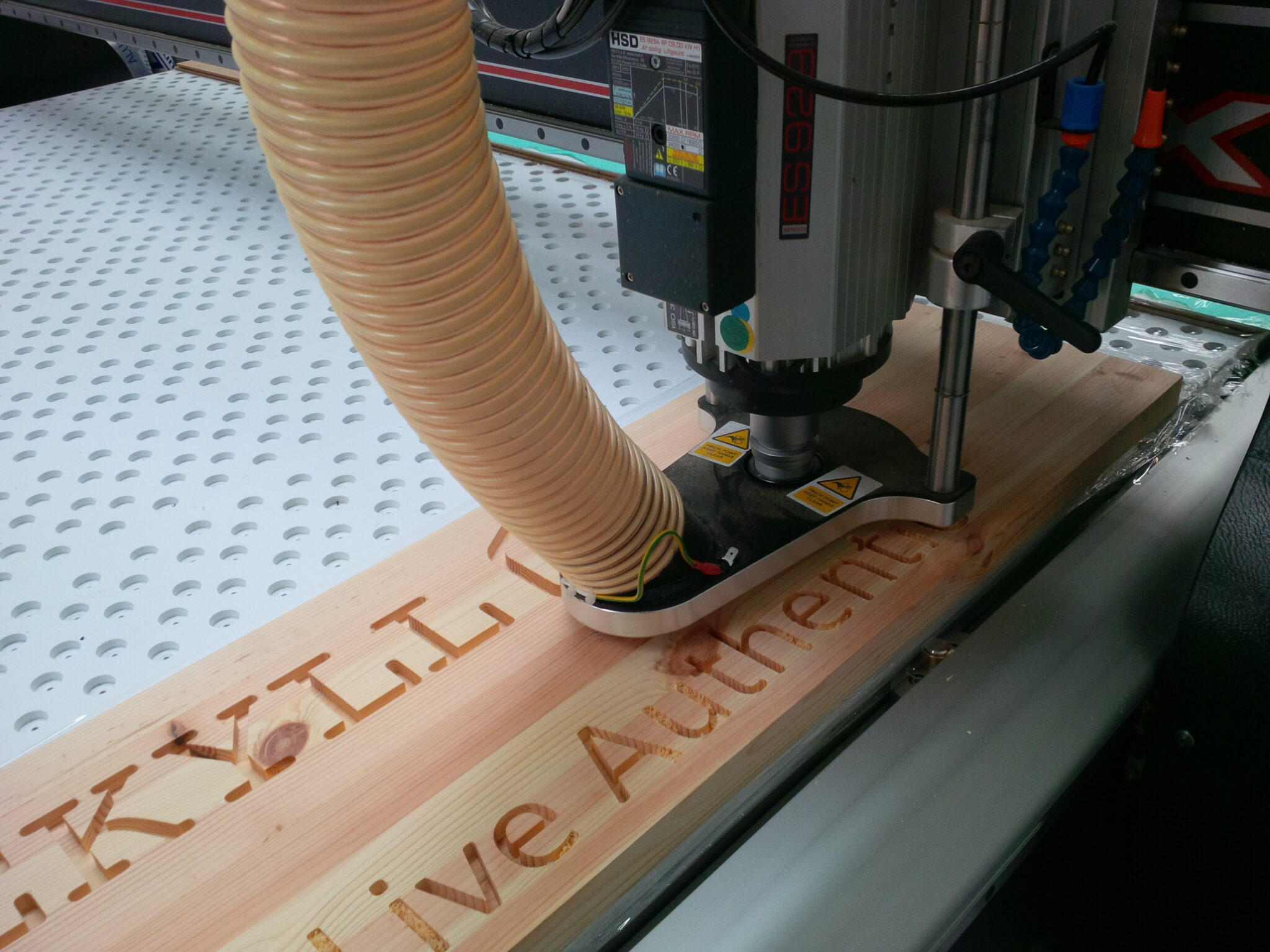

CNC (Computer Numerical Control) machining is a manufacturing process that uses automated cutting, drilling and shaping tools guided by computer programs to deliver high precision components.

In practical terms? It’s how we produce consistent, complex parts — often in plastics or aluminium composite — with tight tolerances, clean edges and reliable repeatability.

CNC machining plays a critical role across industries like:

- Manufacturing & Engineering: Machine components, enclosures, jigs and fixtures

- Signage & Display: Panels, shapes, and exhibition pieces, prepped and ready for branding

- Architecture & Cladding: Custom-cut ACP panels for facades and interiors

- Product Prototyping: Small batch precision parts for fast iteration

- Transport & Automotive: Lightweight custom parts, dashboards, housings and linings

The 5 Factors to Consider

Before you pick a CNC partner, make sure they can deliver on these essentials:

1️. Collaborative Design Support

Do they just take your CAD file and run, or will they actively help you refine it?

A good supplier will advise on how to optimise designs for efficient, cost-effective CNC production — not just press ‘go’ and hope for the best.

2️. Material Versatility

Can they handle the materials you need? Look for expertise in aluminium composite, PVC, acrylic, and other plastics. You want someone who knows how to handle each material for clean finishes, minimal waste and reliable performance.

3️. Precision Manufacturing

Do they deliver consistent, high-tolerance results? For complex geometries or fine detailing, precision isn’t optional. It’s the difference between a component that fits seamlessly and one that needs “adjustment” with a mallet.

4️. Scalable Production

Can they flex from prototype to production? You need a partner who can supply test samples, make iterative improvements, and then ramp up smoothly to full production — without losing a beat.

5️. Responsive Lead Times

Do they meet deadlines — or make excuses? Fast, flexible scheduling and on-time delivery are non-negotiable. You want components ready for integration, not sitting in a queue.

Why Choose Rhino Custom Innovation for CNC Machining?

At Rhino Custom Innovation we combine cutting-edge CNC technology with the kind of hands-on, no-nonsense approach you want from a UK manufacturing partner.

Here’s what we bring to the table:

Precision as Standard: Our CNC machines are tuned for tight tolerances and repeat accuracy from one-offs to high volume runs.

Fast Lead Times: Agile production keeps your project moving. Urgent jobs? We’ll tell you upfront what’s possible (and then deliver).

Flexibility for Custom Work: Bespoke shapes, sizes, materials? No problem. We specialise in the complex, the awkward and the non-standard.

Material Expertise: Aluminium composite, PVC, acrylic — we know how to cut them cleanly, efficiently and reliably.

Sustainable Practices: Through our Rhino Material Recycling Scheme, we recycle CNC offcuts and offer eco-friendly packaging options.

UK-Based Manufacturing: Everything is done in-house at our UK facility, giving you clear communication, short lead times and total control.

Let’s Talk About Your Next Project

If you’re looking for a CNC machining partner who knows their way around a spec sheet and understands the realities of manufacturing deadlines, we’re ready to help.

xxxxxxx— let’s make sure your next project is delivered with precision, speed, and zero headaches.