Workbench Safety in Industry: Full Compliance Guide

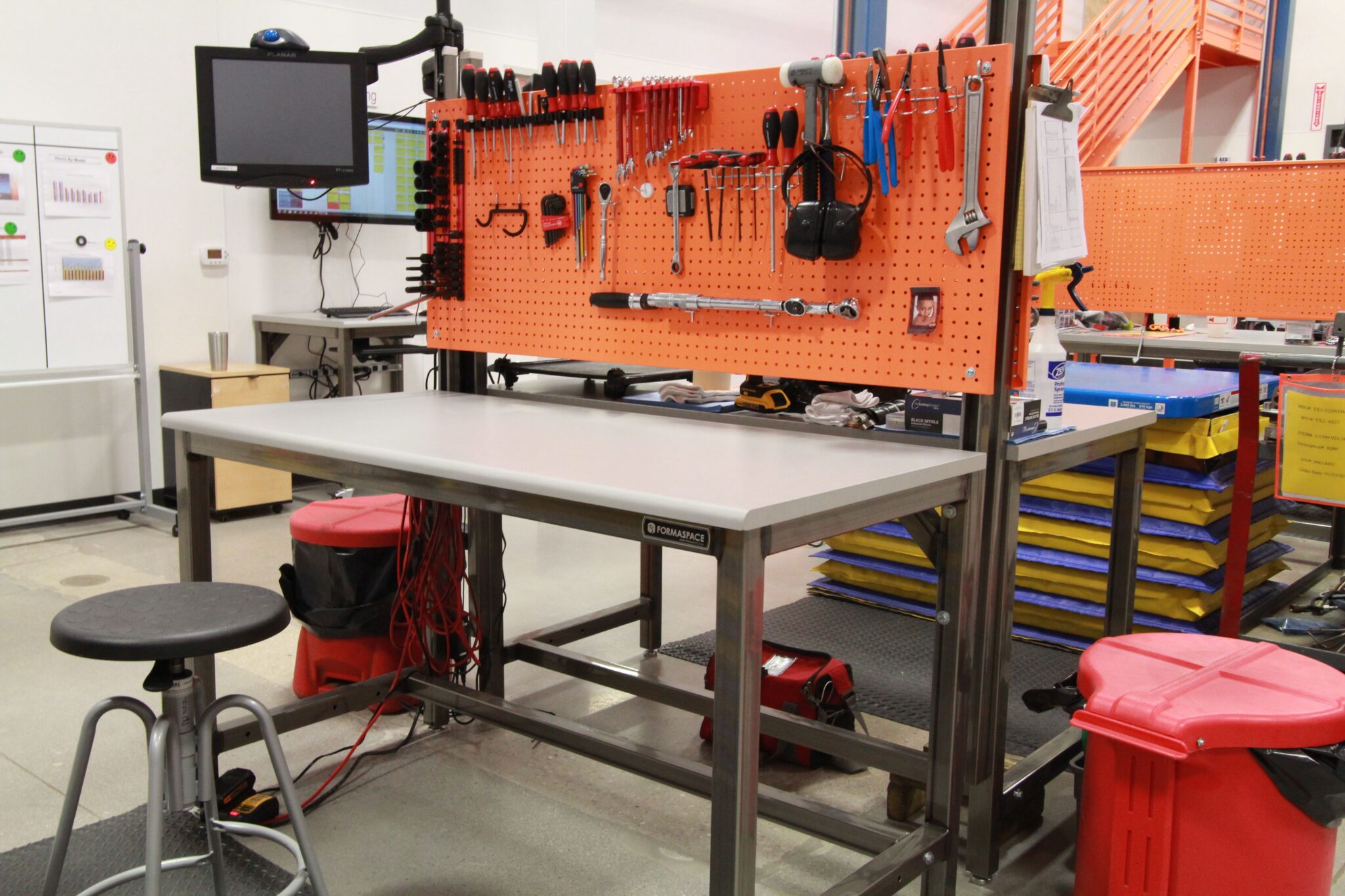

A safe and efficient workplace starts with the right workbench. In industrial environments where heavy tools, precision work and repetitive tasks are part of daily operations, the workbench forms the foundation of both productivity and safety. Yet, it is also one of the most overlooked sources of workplace injury and inefficiency.

This guide outlines a complete industrial workbench safety and compliance checklist to help you maintain legal standards, protect your team and extend the lifespan of your equipment.

Why Workbench Safety Matters

Every year, preventable workplace accidents result in thousands of hours of lost productivity and costly downtime. Many of these incidents are linked to poorly maintained or incorrectly designed workstations.

An unsafe or unstable workbench can lead to repetitive strain injuries, falls or even equipment failure. Beyond physical harm, there are compliance risks too, particularly under the Health and Safety at Work Act and the Provision and Use of Work Equipment Regulations (PUWER).

Keeping your benches compliant ensures:

- Safer, more comfortable working conditions

- Extended equipment lifespan

- Reduced risk of legal penalties

- Improved morale and productivity

UK Regulations and Standards to Consider

In the UK, employers are legally required to provide a safe and compliant working environment. For industrial workbenches, the most relevant standards include:

- PUWER 1998: Ensures that all equipment, including benches, is suitable for use, properly maintained and used by trained staff.

- Health and Safety at Work Act 1974: Establishes the employer’s duty of care to prevent injury and maintain safe working conditions.

- Manual Handling Operations Regulations 1992: Applies to lifting, pushing or pulling activities that occur at the bench.

- Ergonomic Standards (ISO 6385, BS EN 527): Provide guidance on optimal workbench height, reach and posture to prevent strain injuries.

Staying compliant with these standards not only keeps your workforce safe but also protects your business from costly non-compliance issues.

Practical Workbench Safety Checklist

Use this detailed checklist to review your current setup and ensure your workplace meets essential workbench safety, industrial safety standards and workstation compliance requirements. Completing these checks regularly helps prevent accidents, protect staff and reduce costly downtime.

Bench structure stable and load-tested

- Confirm that each bench is sturdy, level and free from wobble or vibration during use.

- Test load capacity to ensure it can safely support the intended weight without strain.

- Address any signs of weakness immediately to avoid structural failure and maintain compliance.

Edges smooth and damage-free

- Smooth, intact edges reduce the risk of cuts and material damage.

- Repair all bench edges and corners for cracks, chips, or sharp areas.

- Replace or refinish damaged surfaces to maintain precision and safety in daily use.

Lighting and ventilation adequate

- Ensure task areas are well-lit to minimise errors and eye strain.

- Maintain proper airflow to remove dust, fumes and heat, especially in workshops using adhesives or solvents.

- Review air filtration systems regularly to uphold safe manufacturing practices.

PPE accessible and in good condition

- Keep personal protective equipment such as gloves, goggles and ear protection readily available.

- Inspect PPE for wear, cracks or contamination before each use.

- Replace damaged or expired items and make sure all staff are trained to use them correctly.

Surface mats clean and intact

- Inspect mats for cuts, delamination or uneven surfaces that could affect grip and accuracy.

- Clean regularly to remove oil, dust and debris that may cause slips or contamination.

- Rhino’s self-healing and ESD protection mats offer durable, compliant solutions that enhance workbench safety.

Electrical connections earthed and tested

- Check all electrical outlets, cables and anti-static equipment for proper earthing.

- Repair damaged wiring immediately to prevent shocks or fires.

- Record all tests and maintenance activities for audit purposes.

Clear floor space with no obstruction

- Keep aisles and walkways around benches free from clutter and tripping hazards.

- Store tools and materials in designated areas to maintain efficiency and order.

- Ensure fire exits, first-aid stations and emergency switches remain accessible.

Inspection records updated and stored

- Maintain written or digital logs of all inspections, repairs and cleaning routines.

- Use these records to track maintenance frequency and demonstrate workstation compliance during audits.

- Review logs monthly to identify recurring issues or areas needing improvement.

All staff trained on workstation compliance

- Provide training on bench operation, cleaning, PPE use and inspection routines.

- Run refresher sessions to reinforce awareness of industrial safety standards.

- Encourage staff to report hazards early and take ownership of their workstation safety.

By applying this checklist routinely, you build a proactive safety culture that supports employee wellbeing, meets compliance obligations and protects the long-term performance of your workbenches and tools.

Strengthening compliance starts with awareness and consistency. Regular inspections, adherence to safety standards and maintaining quality equipment all help reduce risks and improve efficiency. Every workstation element, from bench structure to lighting and ergonomics, plays a role in long-term safety and productivity.

Compliance isn’t a one-off task but an ongoing process built on informed decisions, clear communication and shared responsibility. When teams understand hazards, maintain equipment and follow safe practices, safety becomes part of the culture, protecting people, equipment and operations every day.

FAQs

What are the key elements of workbench safety?

The main factors include structural stability, proper load capacity, smooth surfaces and ergonomic design. Regular inspections, effective lighting and protective mats also play vital roles. Each of these elements helps minimise accidents and supports compliance with industrial safety standards.

How often should industrial workbenches be inspected?

A brief visual check should be carried out daily, with deeper inspections every three months. High-use areas may need monthly assessments to detect wear, loose bolts or surface damage. Keeping written or digital inspection records demonstrates ongoing workstation compliance.

What industrial safety standards apply to workbenches in the UK?

The most relevant standards include the Health and Safety at Work Act 1974, PUWER 1998, and EN 13150 for design and strength requirements. Employers must also consider COSHH and manual handling guidelines. Meeting these ensures your benches meet recognised safe manufacturing practices.

How do protective mats contribute to workbench safety?

Workbench protection mats prevent surface wear, improve grip and reduce vibration. They help protect both tools and operators from accidental slips and strain. Using durable, anti-static or self-healing mats supports safety and extends the lifespan of your workstation.

What is the best way to maintain workstation compliance long-term?

Establish a clear inspection and maintenance schedule, supported by staff training and accurate record-keeping. Review compliance procedures regularly as equipment or regulations change. Embedding safe manufacturing practices into daily routines ensures lasting workplace safety and reliability.