In automotive manufacturing, every moment on the production line counts. Ensuring automotive assembly workstation safety is not just a compliance requirement, it directly affects productivity, product quality and employee wellbeing. Even minor mistakes, such as blade injuries or incorrect cuts, can lead to costly rework, lost hours and disruptions in workflow.

This article explores practical strategies to enhance safety, reduce injuries and minimise rework in automotive assembly workstations. We focus on solutions that combine cutting mats for automotive manufacturing, ergonomic design and structured processes to deliver measurable results.

The Hidden Costs of Blade Injuries and Rework

Blade injuries are more than a safety concern, they carry hidden costs for every production manager. Beyond the immediate impact on a worker, injuries slow down operations, require medical attention and can affect overall team morale. Likewise, rework caused by improper cutting or handling wastes material and adds extra labour.

Studies show that poorly designed workstations and unsafe cutting practices can increase errors by up to 22%. By prioritising automotive assembly workstation safety, manufacturers can protect employees, reduce errors and maintain production efficiency.

Principles of Automotive Assembly Workstation Safety

At the core of effective automotive assembly workstation safety are well-considered design choices, proper training and reliable tools. Key principles include:

- Ergonomic workstations: Reduce strain and support natural movement.

- Standardised cutting procedures: Ensure consistency across operators.

- Safety culture: Encourage proactive reporting and continuous training.

- Reliable equipment: Use high-quality tools and protective surfaces such as cutting mats.

These principles set the overall approach to workstation safety. Detailed step-by-step procedures are explained in later sections.

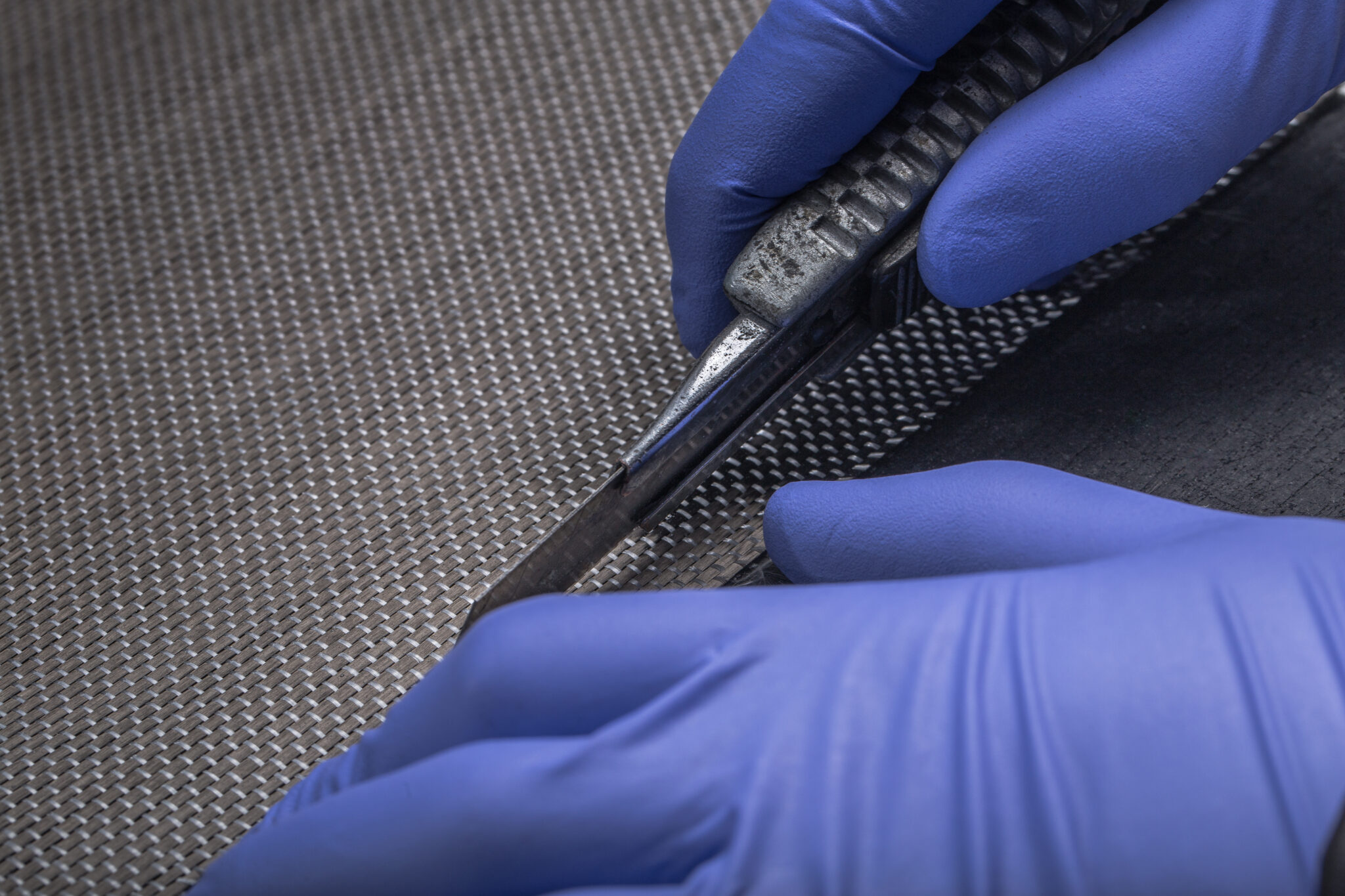

The Role of Cutting Mats in Preventing Blade Injuries

Cutting mats used in automotive manufacturing are simple yet highly effective tools. They provide a stable, non-slip surface that reduces the risk of slips, cuts and accidental damage to components. By protecting both the worker and the material, cutting mats are essential for maintaining both precision and safety. In fact, 77% of clients surveyed reported a reduction in hand injuries after introducing Rhino Cutting Mats into their workstations. This highlights the measurable impact that protective cutting surfaces can have on operator safety and overall production performance.

Benefits of cutting mats include:

- Reduced blade injuries at the workbench

- Consistent, accurate cutting

- Protection of both tools and surfaces

- Improved efficiency and operator confidence

For production managers, integrating cutting mats across assembly workstations is a practical investment. At Rhino Cutting Mats, we provide premium cutting mats specifically designed for automotive manufacturing, helping teams improve safety, reduce errors and maintain high-quality production.

Practical Steps to Reduce Blade Injuries at the Workbench

Reducing the chances of blade injuries at the workbench requires more than just caution, it demands a combination of well-defined processes, proper tools and ongoing training. By implementing practical safety measures, production teams can prevent accidents, maintain workflow efficiency and minimise costly rework. The following strategies are proven to enhance automotive assembly workstation safety while protecting operators on the production line.

Use Cut-Resistant Gloves

Cut-resistant gloves are a fundamental line of defence for operators working with sharp tools. They protect hands without limiting dexterity, allowing workers to maintain precision while handling components. Providing gloves as standard personal protective equipment ensures that minor slips do not result in serious injuries.

Maintain Blades and Cutting Tools

Well-maintained blades and cutting tools are essential for both safety and efficiency. Dull or damaged blades require extra force to cut, increasing the risk of slips and errors. Regular inspection and timely replacement of cutting equipment help maintain sharpness, precision and safe operation throughout the workstation.

Implement Visual Cues

Clear visual cues around cutting zones reinforce safe practices and guide operators on proper procedures. Marked work areas, safety labels and warning signs help workers stay aware of potential hazards, creating a more controlled and predictable environment. Visual management is a simple yet effective way to reduce the likelihood of accidents.

Regular Staff Training

Ongoing training ensures that all operators are familiar with safe cutting techniques, equipment handling and workstation protocols. Training sessions should cover proper posture, cutting angles and emergency procedures. A well-informed workforce is more confident, efficient and less likely to make mistakes that could result in injury or rework.

Install Cutting Mats

Integrating a cutting mat for automotive manufacturing at every workstation provides a stable, non-slip surface for all cutting tasks. Cutting mats protect both the operator and the workpiece, reduce blade injuries at the workbench, and enhance overall control during manual operations.

By combining these strategies, manufacturers can establish a proactive safety culture that not only prevents blade injuries but also supports consistent productivity and high-quality outputs. Implementing these measures is an investment in both employee wellbeing and long-term operational efficiency.

Ergonomic Workstation Design for Reduced Rework

Ergonomics plays a critical role in reducing both rework and workplace injuries on automotive assembly lines. Poorly designed workstations can lead to fatigue, awkward postures, and repetitive strain, all of which increase the risk of mistakes and accidents. By prioritising ergonomic design, manufacturers can create a safer environment that supports consistent, high-quality output.

Best practices include adjustable workstation heights to accommodate operators of all sizes, positioning tools and materials within easy reach, using anti-fatigue mats to reduce strain during long shifts, and ensuring clear, consistent lighting to improve cutting precision. When employees are comfortable and supported, they are less prone to errors, which reduces rework, enhances productivity and contributes to a safer, more efficient workspace.

Production Line Workstation Safety Best Practices

Ensuring production line workstation safety is essential for preventing injuries, reducing rework and maintaining high standards in automotive assembly. A well-organised production line minimises hazards, supports efficient workflows and allows operators to focus on precision tasks without unnecessary risk.

Best practices:

Conduct regular safety audits: Identify potential hazards and ensure all stations comply with safety standards.

Organise tools and materials: Keep work areas clutter-free to prevent accidents and make equipment easily accessible.

Provide clear signage and visual cues: Mark safe zones and cutting areas to reinforce proper practices.

Integrate cutting mats and protective equipment: Ensure every workstation is equipped to minimise blade injuries.

Maintain emergency procedures: Keep first aid kits and reporting protocols readily accessible for quick response.

Benefits of a Preventative Safety Strategy

Adopting a preventative approach to automotive assembly workstation safety delivers measurable benefits:

- Fewer injuries due to protective surfaces and equipment.

- Reduced rework rates thanks to standardised processes and ergonomic stations.

- Improved productivity, as employees work more efficiently and safely.

- Cost savings from lower downtime and less wasted material.

- Enhanced employee morale because a safer environment increases job satisfaction and retention.

Investing in safety is not merely a compliance measure, it is a strategic approach that improves both operational efficiency and workforce wellbeing.

Final Thoughts

Micro-inefficiencies and safety risks at automotive assembly workstations can quietly undermine productivity, quality and operator wellbeing if left unaddressed. For process engineers and production managers, focusing on workbench efficiency manufacturing is one of the most effective ways to improve workflow, reduce rework and enhance operator safety.

By combining ergonomic workstation design, preventative safety measures, ongoing staff training and the integration of high-quality tools and surfaces, small but deliberate improvements can deliver measurable results. Using durable cutting mats from Rhino Cutting Mat helps protect operators, maintain precision and support a consistent, safe workflow across assembly stations.

Ultimately, the most efficient workbenches are those that allow operators to focus entirely on value-adding tasks, backed by well-planned layouts, reliable equipment and a culture of safety and continuous improvement.

FAQs

1. How can automotive assembly workstation safety improve overall production quality?

Improving workstation safety reduces errors caused by operator fatigue, misalignment or unsafe handling. Safer workstations allow teams to maintain consistent assembly standards, reducing defects and ensuring each component meets specifications.

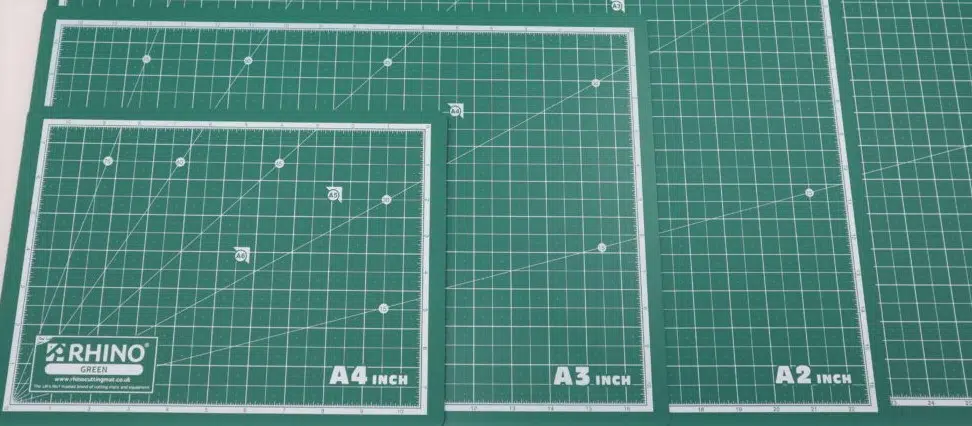

2. Are there specific cutting mats recommended for different automotive manufacturing tasks?

Yes, cutting mats vary in thickness, surface texture and durability. High-density mats are ideal for heavy-duty material cutting, while softer mats suit precise trimming tasks. Choosing the right mat improves accuracy and protects both tools and components.

3. Can workstation layout influence blade injuries at workbenches?

Absolutely. Strategic placement of tools, proper spacing between stations and designated cutting zones minimise accidental contact with sharp edges. A thoughtful layout reduces risks and improves workflow efficiency.

4. How does employee engagement affect production line workstation safety?

Engaged operators are more likely to follow safety protocols, report hazards and use protective equipment consistently. Encouraging active participation in safety programs strengthens culture and reduces the likelihood of injuries or rework.

5. What role does maintenance of workstations play in reducing accidents?

Regular inspection of work surfaces, tools and safety equipment ensures everything functions correctly. Proactive maintenance prevents tool malfunctions, loose mats or uneven surfaces that could lead to slips, cuts or misaligned components.