Choosing the best cutting mats for your workspace is one of the simplest ways to improve accuracy, protect your tools and maintain a safer, cleaner environment. Whether you are working in a busy production area, a school, a craft room or an office, the right cutting mat supports smoother cutting, reduces surface damage and helps you work with confidence.

This buying guide explains what makes a good cutting mat and how to choose the right option for craft, industrial and office use.

What Makes the Best Cutting Mats?

The best cutting mats combine durability, surface stability and reliable self-healing performance. They stay flat, resist deep scoring and provide enough grip to hold materials in place without damaging blades.

A high-quality cutting mat also improves safety by reducing slips and helping tools glide smoothly through materials. Rhino cutting mats are designed for long-term use, helping to reduce replacement costs while maintaining consistent cutting accuracy.

Key Features to Look For in a Cutting Mat

Self-Healing Surface

A self-healing surface closes after each cut, keeping the mat smooth and preventing permanent grooves. This protects both the mat and your blades, extending their lifespan.

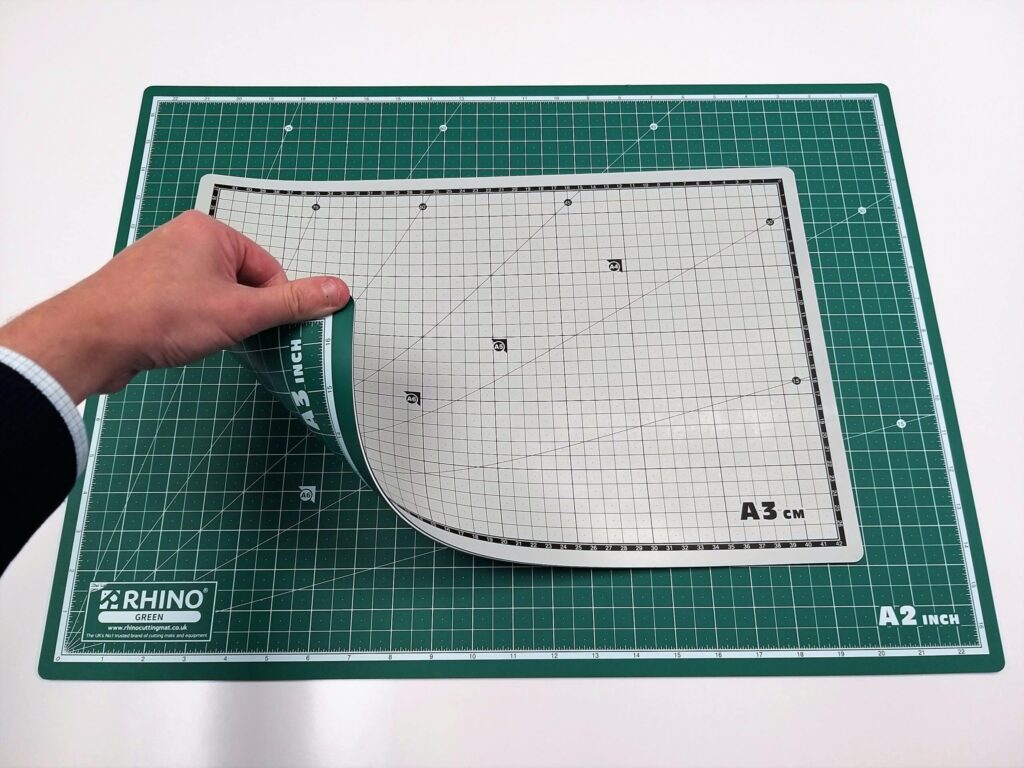

Thickness and Duty Level

Thicker mats are better suited to heavy or repetitive cutting, while mid-thickness mats work well for craft and office tasks, where flexibility and portability matter.

Surface Grip and Stability

A cutting mat should stay firmly in place during use. A stable, non-slip surface improves accuracy and significantly reduces the risk of hand injuries.

Material Strength

Quality mats resist warping, curling and cracking over time. This ensures a flat, predictable cutting surface every time you work.

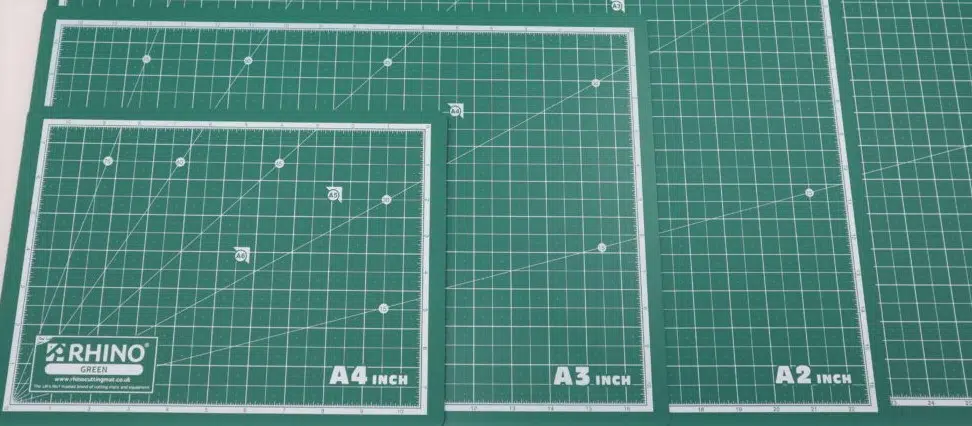

Correct Sizing

The right size mat allows you to work comfortably without overhanging edges or cramped cutting areas. Larger mats reduce strain by allowing you to reposition materials easily.

Best Cutting Mats by Work Environment

Different environments place different demands on a cutting mat. Below is a clear breakdown of what to look for in a craft, industrial and office cutting mat.

Best Craft Cutting Mat

A craft cutting mat needs to provide a smooth, forgiving surface for precision work. It should be stable enough for detailed cuts while remaining light and easy to move.

Ideal for quilting, sewing, paper crafting, model making and card production, a good craft mat supports clean cuts without damaging delicate materials.

Recommended features

- Self healing surface

- Clear grid lines for accurate measuring

- A2 or A3 sizing for desk-based work

- Mid-thickness construction for comfort and control

Why it matters

Craft work often involves fine cuts and repeated scoring. A stable mat prevents drag, protects materials and helps blades stay sharp for cleaner results.

Best Industrial Cutting Mat

An industrial cutting mat is built for high-pressure applications and demanding workshop environments. It must withstand constant use, sharp blades and long material runs without degrading.

Recommended features

- Extra-thick construction for durability

- Non-slip surface for improved safety

- Full bench or custom sizing options

- Resistance to abrasion and chemicals

- Consistently flat surface under pressure

Why it matters

In industrial settings, cutting mats protect workbenches, improve workflow and reduce tool replacement costs. A reliable surface also lowers the risk of injuries during repetitive tasks.

Best Office Cutting Mat

An office cutting mat supports everyday tasks such as trimming documents, mounting displays, packaging materials and light design work. It should be compact, neat and easy to store.

Recommended features

- A3 or A2 sizing for practicality

- Self-healing surface for clean cuts

- Subtle colour and professional finish

- Lightweight design for portability

Why it matters

A good office cutting mat protects desks, improves presentation quality and allows accurate trimming of paper, posters and samples without damaging furniture.

How to Choose the Right Cutting Mat

1. Assess Your Workload

Frequent or heavy cutting requires a thicker, more durable mat. Light or occasional tasks can be handled with a mid-thickness craft or office mat.

2. Measure Your Workspace

Ensure your mat fits comfortably on your desk or bench without overhanging edges. Leaving a small border around the mat improves stability.

3. Match the Mat to Your Materials

Large materials such as vinyl, fabric and foamboard benefit from A1 or A0 mats. Smaller projects are well suited to A2 or A3 sizes.

4. Prioritise Safety

A stable, non-slip mat helps maintain blade control and reduces the risk of accidents, especially during detailed or repetitive cutting.

5. Choose Long-Term Value

High-quality mats last longer, protect blades and maintain cutting accuracy over time. This makes them more cost-effective in busy or shared environments.

Find the Right Cutting Mat for Your Workspace

Ready to choose the best cutting mats for your workspace? Whether you need a craft cutting mat, an industrial cutting mat or a versatile office cutting mat, Rhino offers durable options built for long-lasting performance. Explore the full range or request a custom size to fit your bench perfectly.

Cutting Mat FAQs

Which cutting mat size is best?

This depends on your materials and available space. Large projects suit A1 or A0 mats, while A2 or A3 works well for desk-based tasks.

How thick should a mat be for heavy use?

Industrial environments require thicker mats that can withstand repeated pressure and deep cuts without deforming.

Do self healing mats really last longer?

Yes. The surface closes after each cut, preventing grooves and maintaining a smooth cutting area for longer.

Why does my mat warp or curl?

Warping is usually caused by heat, sunlight or vertical storage. Always store mats flat in a cool, dry area.

Why do my blades go blunt quickly even when using a cutting mat?

Blades often go blunt faster when the cutting mat is too thin or made from low-quality materials. A weak or worn surface offers little resistance control, forcing the blade to work harder with each cut. This increases friction and accelerates blade wear. A high-quality, self healing cutting mat with a stable surface allows the blade to glide smoothly, reducing resistance and helping it stay sharper for longer.

Can one mat work for craft and industrial use?

No. Craft mats are not designed for heavy-duty cutting. Industrial tasks require thicker, more robust mats.

How do I stop my mat slipping?

Choose a mat with a non-slip base and ensure it is correctly sized for your surface.

How should I clean a cutting mat?

Use a damp cloth only. Avoid harsh chemicals and hot water.

How long should a good cutting mat last?

With correct use and storage, a high-quality mat can last for years, especially heavy-duty options.

Can I order a custom size?

Yes. Rhino offers custom sized cutting mats to fit exact bench dimensions.