Whether you’re a precision engineer, craft designer or production manager, cutting mats are the quiet workhorses behind cleaner, safer and more accurate results. These essential surfaces protect workbenches, extend tool life and improve overall efficiency across industries from high-volume manufacturing to fine art studios.

At Rhino Cutting Mat, we’ve spent two decades refining the performance and durability of our cutting mats, developing solutions trusted by major industrial clients, universities and creative professionals across the UK.

Our mission is simple: to help people work smarter, safer and cleaner with cutting surfaces designed to last longer, reduce waste and support sustainable innovation.

What Is a Cutting Mat and How Does It Work?

A cutting mat is a resilient, multi-layered surface engineered to absorb the pressure of blades and rotary cutters while protecting both the workpiece and the workbench beneath.

High-performance cutting mats such as Rhino’s SupaSeal and Ultraseal models feature self-healing technology, a unique structure that closes minor cuts automatically, maintaining a smooth working surface and ensuring straighter, cleaner cuts over time.

For industrial users, a quality cutting mat also enhances safety, accuracy and cost control, reducing tool wear by up to 50% and preventing costly bench replacements.

Types of Cutting Mats (By Material, Purpose and Sector)

Type | Key Features | Best For |

Multi-layered with elastic recovery | General industrial and design use | |

Carbon-infused surface dissipates static | Electronics, aerospace, composite manufacturing | |

Dense, non-slip material | Workshops, education, signage | |

High impact resistance | Metalwork and engineering benches | |

Custom Size Mats | Tailored to workstation dimensions | Bespoke production lines or laboratories |

Each category is available in a variety of thicknesses, colours and finishes to suit workspace ergonomics and brand requirements.

Key Technical Features to Look For

When comparing cutting mats, prioritise the following specifications:

Size & continuity: In industrial setups, you may require large one-piece mats (e.g. up to 5m long) to avoid creating joints, which can trap debris.

Thickness & hardness (shore rating): Heavier-duty mats are designed to handle tougher cutting tools and provide a longer lifespan. For example, when cutting carbon fibre, Rhino recommends using a mat approximately 6mm thick with a shore hardness of around 70.

Surface finish & material compatibility: For composite manufacturing or cleanrooms, you’ll want surfaces that don’t trap fibres, shed dust or contaminate. Wooden tops are to be avoided because wood fibres and resins may contaminate composites.

Cleanability & chemical resistance: Essential if you are working with adhesives, resins, solvents and sanding debris. The surface must be wipeable, non-porous.

Self-healing quality: A good self-healing mat doesn’t accumulate grooves, which degrade precision and blade life.

ESD / static control: If you operate in electronics, aerospace or medical device assembly, you may need mats that dissipate static or have anti-static properties.

Customisation & sample packs: If your workbench is non-standard, choosing a supplier that offers custom sizes and sample packs helps. Rhino offers free sample packs (to UK business addresses).

Advanced Industrial Use Cases

Below are three advanced industrial scenarios and how a high-quality cutting mat contributes — including real references from Rhino’s own materials.

1. Cleanrooms & Electronics Assembly

In electronics assembly, medical device production or semiconductor environments, work surfaces must meet exacting standards of cleanliness, static control and dimensional precision.

- Contamination control: A workbench surface that sheds fibres, traps debris or has deep grooves becomes a contamination risk. In cleanrooms this is critical, as even tiny particles may compromise assemblies.

- Static control: Tools, materials and boards in electronics manufacture are sensitive to electrostatic discharge (ESD). A mat that is anti-static and safe for ESD zones is vital. Rhino’s product line includes ‘StaticSafe ESD Bench Mat’ and ‘Xtratuff ESD Work Surface’.

- Durability and large size: In production, you may have long runs of workstations; using a continuous self-healing mat ensures uniform performance and fewer transitions.

- Precision surface: Cuts must be exact; any surface warping or irregularity will impact yield. A thick high-performance mat ensures consistent support.

2. Composite-Material Manufacturing (Carbon Fibre, Kevlar, Aerospace)

In aerospace, automotive lightweighting and advanced materials, composite manufacturing demands exacting conditions. The work surface, which may serve for cut-ply laminate operations, trimming, deburring, must meet high standards.

- Cross-contamination risk: Wooden tops or mats that shed fibres can introduce contamination into composite layers.

- Blade interaction: Composite cloths often require heavy duty knives; the mat needs to allow blade movement, not dull blades prematurely, and be tough enough to resist gouging. Rhino recommends Ultra-Seal mats with shore 70 for this usage.

- Large, continuous area: Large workbenches in laminate lay-up may require mats in one piece to avoid joined seams.

- Clean and chemical resistant: Mat surfaces must resist pre-preg resin, solvents, sanding dust and fibres.

- Safety & durability: The surface must not deform under process load, must maintain flatness and resist wear.

3. Workshop, Sign-making & Heavy Duty Fabrication

In workshops, sign-making, vinyl cutting, routing and heavy-duty fabrication, cutting mats still play a vital role.

- Large format cutting: For example, in sign studios, mats of 8′×4′ (or larger) are used to cut sintra, foam board, acrylic sheets.

- Blade and table protection: Heavy knives and cutters can damage table surfaces; premium mats mitigate this.

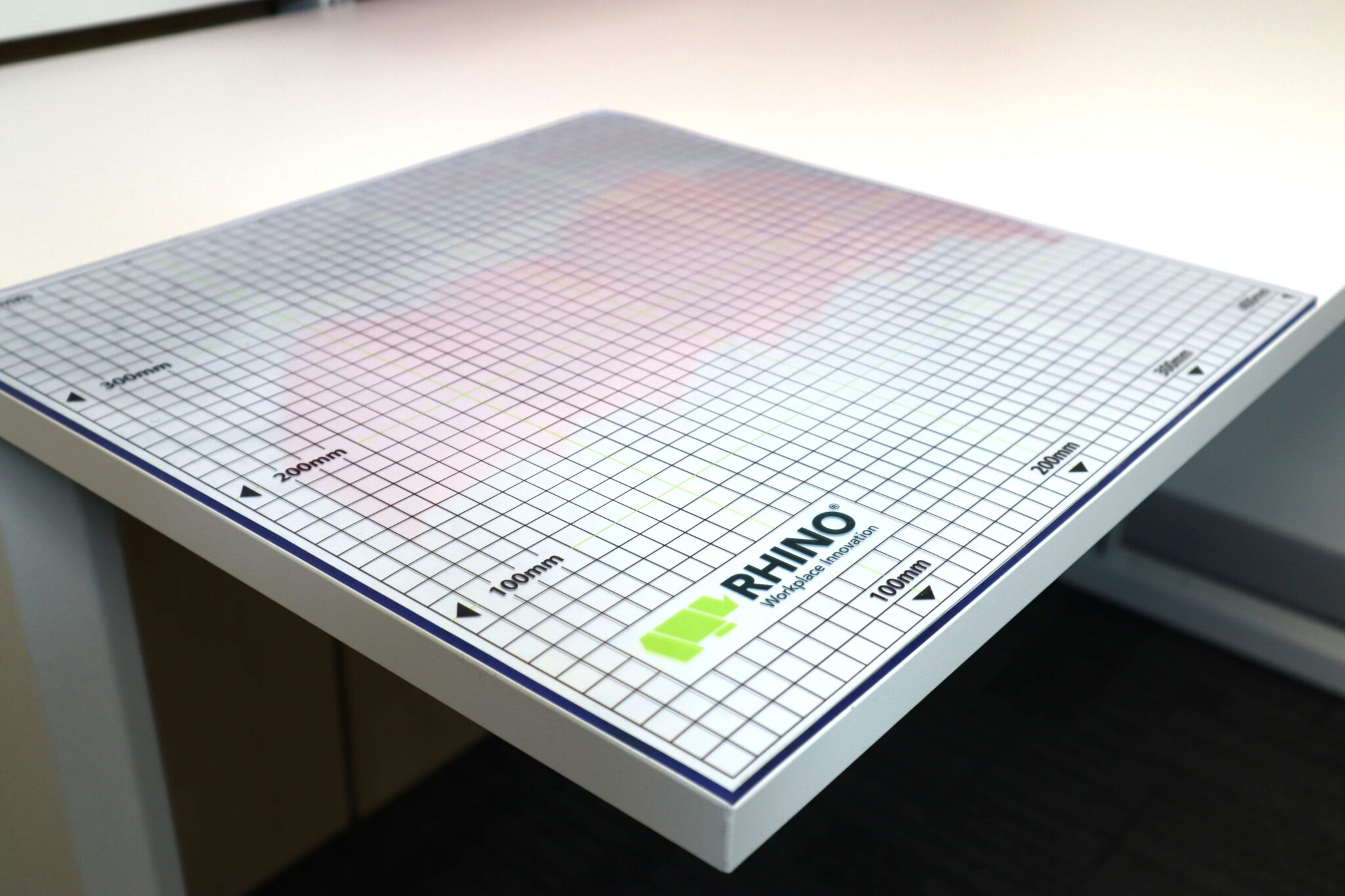

- Grid overlays: For signage and vinyl cutting, printed grids help alignment of large panels.

- Custom sizes: Rhino’s product range includes custom-sized mats to suit production tables.

- 45-degree & custom angles: Some workflows require printed angle guides and precision layouts; mats may support this.

- Durability under load: In a heavy workshop environment, your mat might see repeated abuse; selecting a durable self-healing version is wise.

Sector-Specific Applications

- Manufacturing and Warehousing: Protect benches on packing and trimming lines.

- Automotive and Aerospace: Maintain accuracy in carbon-fibre component prep.

- Workshops and Garages: Durable mats withstand oils, solvents and heavy use.

- Craft and Textiles: Ideal for fabric cutting, pattern drafting and rotary tools.

- Education and Training: Safe, clean work surfaces for Design and Technology departments.

- Signage and Printing: Smooth, self-healing mats extend tool life and maintain sharp lines.

How to Choose the Right Cutting Mat (Expert Checklist)

Selecting the right cutting mat ensures accuracy, efficiency and long-term performance. Before purchasing, consider the following expert tips to match your workspace and workflow needs:

- Identify your work environment: Decide where the mat will be used, such as a cleanroom, workshop, classroom or design studio. Each setting has its own safety and cleanliness standards.

- Determine the required size and thickness: Larger workbenches benefit from thicker mats that provide better stability and protection from heavy tools or repeated cuts.

- Consider anti-static or heat-resistant features: ESD-safe cutting mats are essential for electronics and composite manufacturing environments.

- Choose a colour and texture to enhance visibility: Grey or black surfaces reduce glare, while smooth finishes are ideal for precision cutting.

- Opt for custom sizing: Bespoke mats prevent gaps or overhangs, improving efficiency, comfort and safety.

- Check warranty and sustainability credentials: Look for extended warranties and recyclable materials to ensure durability, value and environmental responsibility.

Best Practices: Installation & Maintenance

- Flat, stable substrate: Ensure the underlying bench surface is flat and rigid; flexing or movement underneath will reduce cutting accuracy.

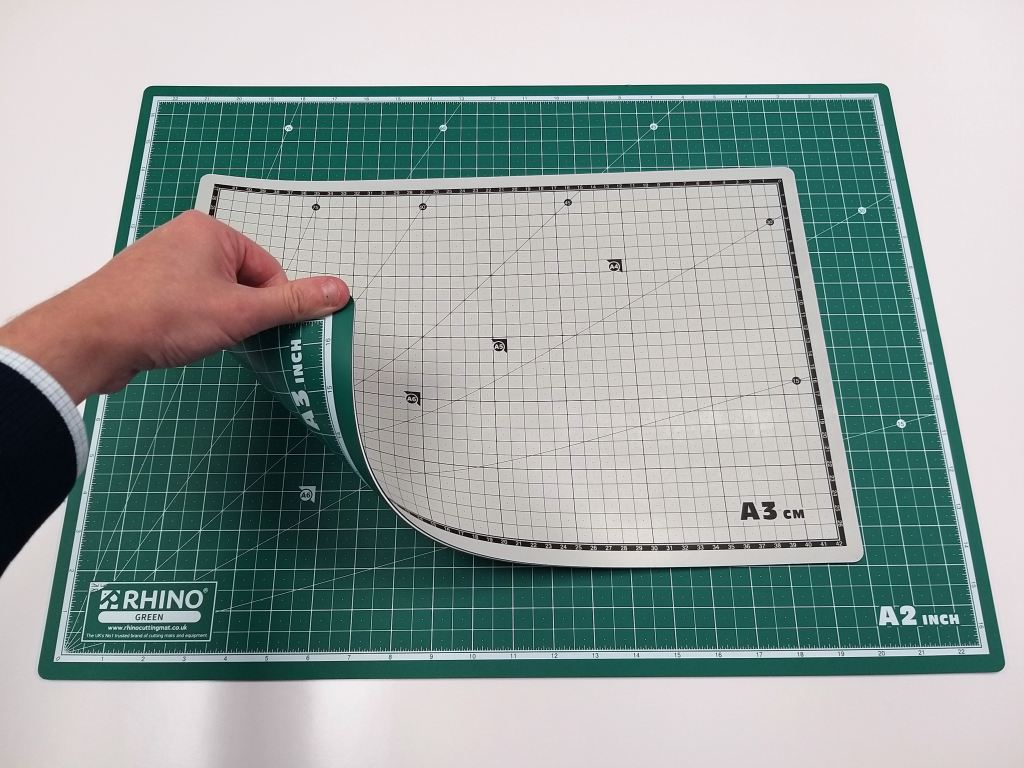

- Allow for mat expansion/flat-out time: Large mats often arrive rolled; allow them to lie flat for some hours before use.

- Keep multiple cutting zones: Do not keep cutting repeatedly in the exact same spot — this concentrates wear.

- Clean regularly: Especially in composite or cleanroom environments, wipe down using suitable cleaning agents. Avoid materials that shed.

- Replace when necessary: Even self-healing mats have a life. If you see grooves or surface degradation, replace before it impacts precision or safety.

- Compatibility with tools: If you use heavy routing, sanding or punching equipment, ensure your mat is rated for such loading; some mats may crack or deform under mallet or impact loads.

- Edge treatment for large size mats: For very large mats, consider bevelled or taped edges to avoid tripping hazards or material catching.

- Delivery & sample requests: As a UK-based business example, Rhino provides free sample packs for UK business addresses, a useful way to evaluate mat properties before full purchase.

Why Choose Rhino Workplace Innovation

With more than 20 years of UK-based design and manufacturing expertise, Rhino Workplace Innovation continues to set the standard for precision, durability and environmental responsibility in cutting mats. Every Rhino product is engineered to help professionals work smarter, safer and cleaner across all sectors, from advanced manufacturing to design and education.

“Our customers rely on consistency. Every Rhino mat is engineered for repeatable accuracy and long-service life.”

Jake Douglass, Founder and Managing Director

Rhino’s reputation is built on proven performance and verified 4.9-star service excellence, supported by a 5-year warranty on selected products. Customers repeatedly praise the company’s product quality, reliability and personal service.

What Our Customers Say

All reviews are sourced from verified buyers on Reviews.co.uk.

Steve Canning – Verified Buyer

“I ordered a bespoke size self-healing mat as desktop protection and it arrived early and was cut to perfection and was a simple install. I would therefore recommend Rhino Workplace Innovation.”

Lucie Skates – Verified Buyer

“Easy to order and pay. Dispatched the next day as stated, arrived rolled in a sturdy box, and the mat 800×1600 was flat in a short period of time.”

Jo Clark – Verified Buyer

“Great company. We had an issue with a mat we bought and it was resolved quickly with no fuss. Highly recommend this company.”

Tom Coates – Verified Buyer

“Great products, great quality, and great pricing. Not only the products but the customer service and ease of ordering have been very useful for us.”

Peter Bryan – Verified Buyer

“Excellent, met our expectations, and we will be using Rhino again.”

Rhino’s long-standing commitment to customer satisfaction, technical innovation and sustainable product design makes it the trusted choice for professionals who demand the best in cutting mats and workbench protection solutions.

Rhino Cutting Mat Comparison Guide

Product | Thickness | Key Feature | Best Use |

SupaSeal Black | 5 mm | Self-healing PVC surface | General cutting and workbench protection |

XtraTuff ESD | 4.5 mm | Carbon-infused anti-static layer | Electronics and composite fabrication |

SupaSeal Grey | 5 mm | Non-reflective surface | Clean visual aesthetic for design studios |

Frequently Asked Questions

Q1: What’s the difference between self-healing and standard cutting mats?

Self-healing cutting mats are designed with multiple micro-layers that automatically close up after each cut. This allows the surface to remain smooth, preventing blade snagging and ensuring consistent accuracy over time. Standard mats, by contrast, tend to retain cut marks, which can affect precision and shorten tool life. A self-healing surface also provides better value long term, as it lasts significantly longer and requires less frequent replacement.

Q2: Can cutting mats be used in cleanrooms?

Yes. Certain cutting mats such as Rhino’s Ultraseal, Heavy-Duty and XtraTuff ESD range are specifically developed for cleanroom and controlled environments.They also comply with ISO 14644 standards, making them suitable for industries like aerospace, pharmaceuticals and advanced manufacturing.

Q3: How long do industrial cutting mats last?

The lifespan of industrial cutting mats depends on their material, thickness and frequency of use. Rhino mats are engineered for durability and can last up to 75% longer than standard alternatives when properly maintained. Regular cleaning, rotating the mat, and storing it away from heat will help extend its service life. Many Rhino customers report years of reliable performance, even in high-volume production environments.

Q4: Are Rhino cutting mats recyclable?

Yes, Rhino is committed to sustainability through its Mat Recycling Scheme, which allows customers to return end-of-life mats for responsible processing. Materials are repurposed or recycled wherever possible, reducing waste sent to landfill. Rhino also uses recyclable packaging and continues to explore PVC-free product options. Choosing Rhino means supporting a greener, more circular manufacturing approach without compromising on quality or performance.

Q5: Do cutting mats improve tool lifespan?

Absolutely. High-quality cutting mats like Rhino’s SupaSeal range reduce friction and blade impact during use, helping to maintain sharper cutting edges for longer. By absorbing pressure and providing a stable surface, they prevent premature tool wear and bending. This results in cleaner, more accurate cuts and reduces replacement tool costs by up to 50%. Over time, this translates into significant savings for both industrial and creative professionals.