When you’re producing bespoke components, panels or display pieces, there’s more than one way to get an accurate cut or a crisp engraved detail. Two of the most popular methods are laser cutting and CNC engraving — and while they sometimes get mentioned in the same breath, they’re very different tools with different strengths.

At Rhino Custom Innovation, we use both in our workshop. Which one we choose depends on the material, the finish, and the level of detail the project calls for. Here’s how they compare.

How Each Process Works

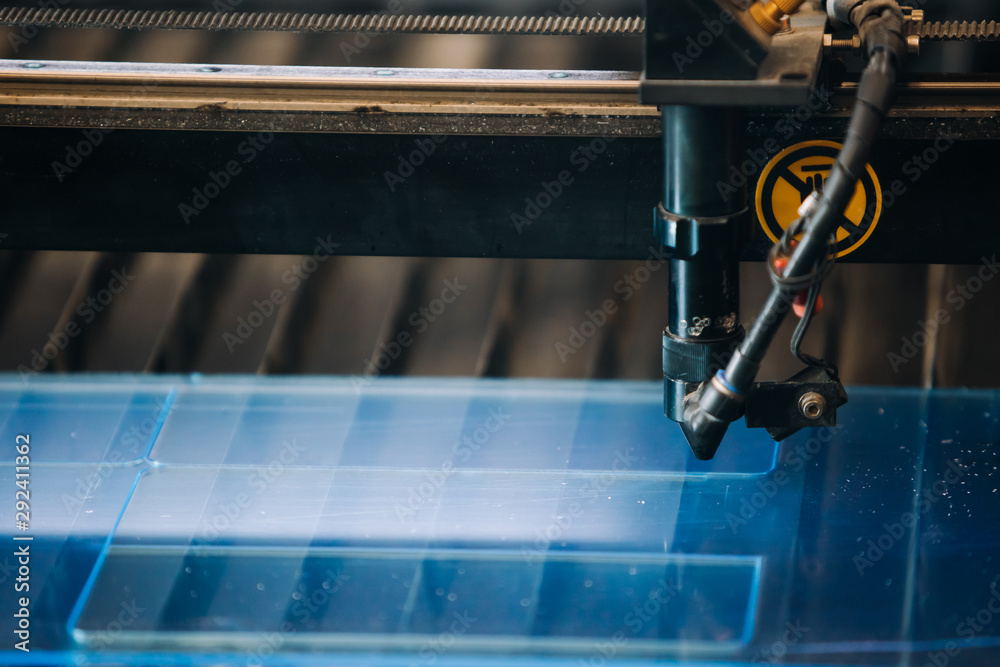

Laser cutting and engraving use a focused beam of light to burn, melt or vaporise material along a programmed path. The process is contact-free, so there’s no tool pushing against the material — meaning extremely fine details are possible.

Our laser machines accept artwork in formats like DXF, DWG, EPS or AI. Once programmed, they work out the most efficient sheet yield, the shortest cutting path, and the right cutting depth or number of passes. With a cutting area of 1200 x 900mm, they’re ideal for small to medium-sized parts, especially with intricate features.

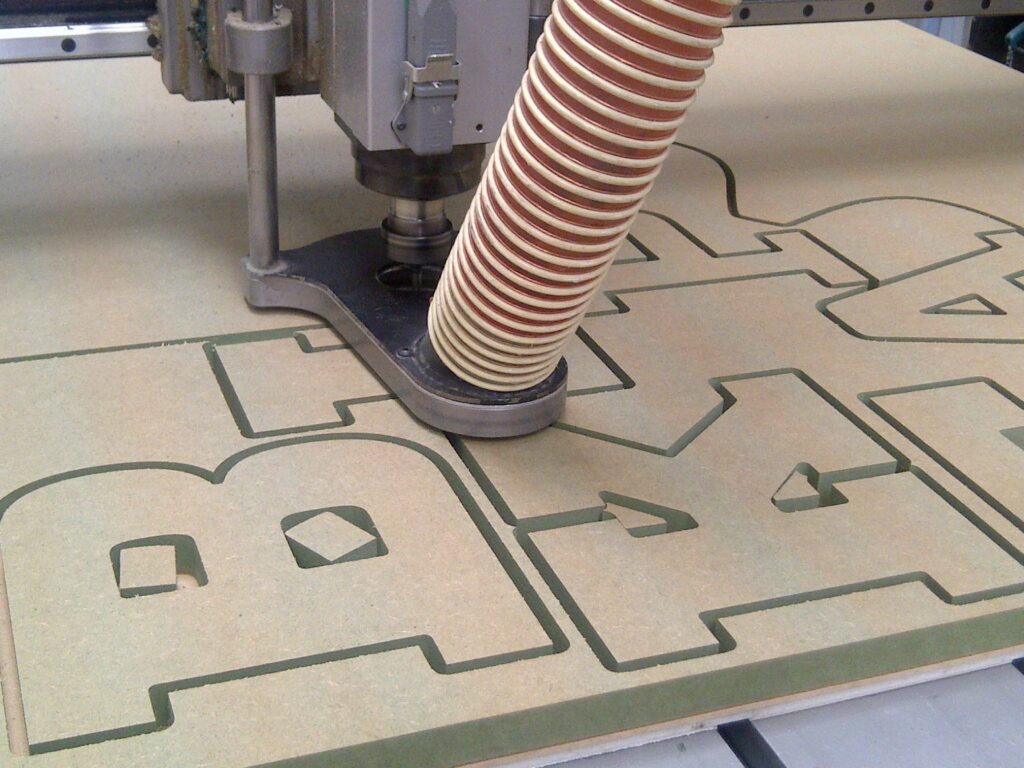

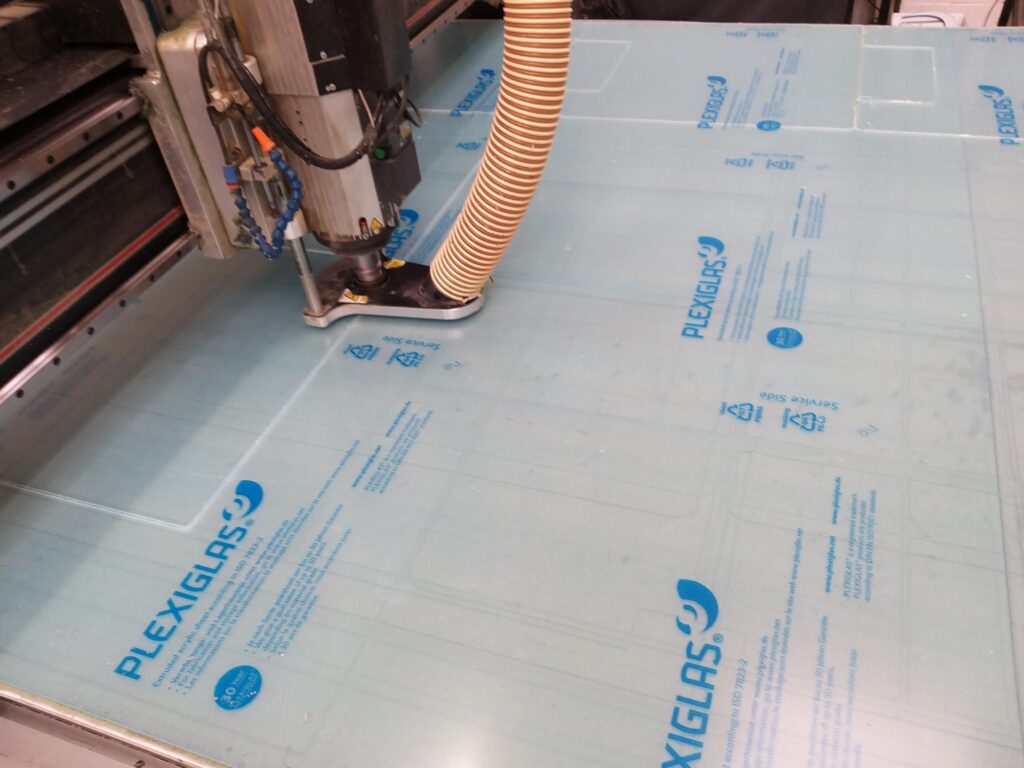

CNC engraving, on the other hand, uses a rotating cutting tool to physically remove material. This allows for a different range of materials and depths, as well as the ability to create V-grooves, bevels and precise pockets. Because the tool is physically in contact with the workpiece, CNC can handle thicker, denser materials that laser can’t cut through.

Advantages of Laser Cutting & Engraving

Laser is at its best when you need:

- Intricate, fine details — perfect for items viewed up close, such as point-of-sale displays.

- Polished edges on acrylic — the laser leaves a smooth, clear edge straight off the machine, no post-finishing required.

- High repeatability — every part in a batch will match within 0.1mm.

- Delicate engraving — great for surface marking, branding or decoration without deep cutting.

The main limitation? Material thickness. In practical terms, laser cutting is best for sheet material up to around 10mm thick.

Advantages of CNC Engraving

CNC engraving excels where laser can’t go:

- Thicker materials — easily handles sheets well over 10mm.

- Material variety — works with plastics, aluminium composite, solid aluminium, wood and more.

- 3D contouring — creates bevels, chamfers and pockets that a laser can’t produce.

- Durable markings — engravings are cut into the material rather than marked on the surface.

Because CNC is a mechanical process, it also avoids the heat-affected edges you sometimes see with laser cutting, which can be important for certain engineering applications.

Which One Should You Choose?

The right choice depends on your priorities:

- If your design features very fine details, is made from thin acrylic or rigid plastic, or needs a polished edge straight off the cutter, laser is often the better choice.

- If you’re working with thicker stock, need structural engravings or require machining in aluminium composite or other tougher materials, CNC engraving is usually the way to go.

At Rhino, we’ll often use both processes on the same project — for example, CNC routing a panel to shape, then laser-engraving graphics or text for a crisp finish.

Laser vs CNC Engraving: Quick Comparison

Feature / Consideration | Laser Cutting & Engraving | CNC Engraving |

Process | Uses a focused laser beam to cut or mark material – contact-free. | Uses a rotating cutting tool to physically remove material. |

Best For | Thin acrylic, rigid plastics, PETG, polycarbonate, fine graphics, surface engraving. | Aluminium composite, solid aluminium, thicker plastics, wood, deeper engravings, 3D contours. |

Typical Thickness Capacity | Up to ~10mm (varies by material). | 0.5mm to 50mm+ (depends on tooling and material). |

Edge Finish | Smooth, polished edge on acrylic straight from the machine. | Machined edge — may require light finishing depending on material. |

Detail Level | Extremely fine detail possible (within ±0.1mm tolerance). | High precision, but minimum tool size limits the tiniest details. |

Material Range | Acrylic, PETG, polycarbonate, some thin woods and laminates. | Wide range: plastics, aluminium composite, metals, woods, foams. |

3D Capabilities | 2D cutting and surface engraving only. | 2D and 3D cutting, bevels, chamfers, pockets and V-grooves. |

Speed | Very fast on thin, intricate parts. | Fast on thicker, less intricate shapes; slower for fine details. |

| ||

Heat Impact | May create a small heat-affected zone on some materials. | No heat-affected zone; purely mechanical cutting. |

Repeatability | Excellent — identical parts within ±0.1mm. | Excellent — precision maintained across batches. |

How Rhino Adds Value

Because we run both laser and CNC machinery in-house, we can:

- recommend the process that gives you the best balance of cost, lead time and finish.

- combine techniques for complex, multi-stage jobs.

- handle a wide range of materials, from acrylic and polycarbonate to aluminium composite and rigid plastics.

- maintain tight quality control on every part, whether it’s one prototype or a full production run.

In Summary

Laser and CNC engraving each have their strengths. Laser delivers unmatched fine detail and a beautiful finish on acrylic and plastics, while CNC engraving provides more material flexibility, depth and structural options. Knowing which to use — and when — is the key to getting the result you want. Talk to Rhino Custom Innovation. We’ll match your design to the process that delivers the right look, feel, and function — every time.