In high-performance manufacturing environments, productivity gains rarely come from dramatic overhauls alone. More often, they are unlocked by identifying and correcting small, repeated inefficiencies that quietly erode output every day. These micro-inefficiencies, extra movements, poorly placed tools, inconsistent work surfaces or awkward layouts, can cost minutes per shift and thousands of pounds over a year.

For process engineers, improving workbench efficiency in manufacturing is one of the most practical ways to reduce waste, improve quality and support lean manufacturing goals. The workbench is where value is created, decisions are executed and small inefficiencies either compound or disappear.

This article explores how process engineers systematically identify, reduce and eliminate micro-inefficiencies at the workbench using proven methodologies, ergonomic design principles and continuous improvement frameworks.

Understanding Micro-Inefficiencies in Manufacturing Workbenches

Micro-inefficiencies are small, often overlooked sources of waste that occur at individual workstations. Unlike major bottlenecks, they are easy to ignore, but their cumulative impact is significant.

Common examples include:

- Operators reaching repeatedly for poorly positioned tools

- Inconsistent cutting or working surfaces causing rework

- Searching for consumables or components

- Excess motion due to cluttered or poorly organised benches

- Inadequate surface protection leading to damaged tools or benches

From a lean manufacturing perspective, these issues directly relate to motion, waiting and defects, three of the classic forms of waste.

For process engineers focused on process improvement workstations, the challenge is not just spotting inefficiencies, but understanding how small ergonomic and layout decisions influence operator behaviour over time.

The Role of Process Engineers in Workbench Efficiency Improvement

Process engineers play a critical role in translating lean principles into practical, floor-level improvements. Their responsibility goes beyond documentation and standard work — it includes designing environments that naturally encourage efficiency.

In the context of workbench efficiency manufacturing, this means:

- Observing real operator behaviour rather than relying on assumptions

- Using time-and-motion studies to quantify inefficiencies

- Collaborating with operators to identify friction points

- Implementing low-cost, high-impact improvements

Experienced engineers know that the most effective changes often come from asking simple questions:

- Why is this tool placed here?

- How often is this surface damaged or replaced?

- How many steps does an operator take per cycle?

These insights form the foundation of sustainable process improvement workstations.

Industrial Workbench Setup: Designing for Flow and Ergonomics

An effective industrial workbench setup supports both process flow and human performance. Poor layout decisions increase fatigue, introduce variation and slow cycle times.

Key design considerations include:

Ergonomic Height and Reach

Workbenches should be set to minimise bending, stretching and wrist strain. Adjustable benches allow accommodation for different operators and tasks.

Consistent, Durable Work Surfaces

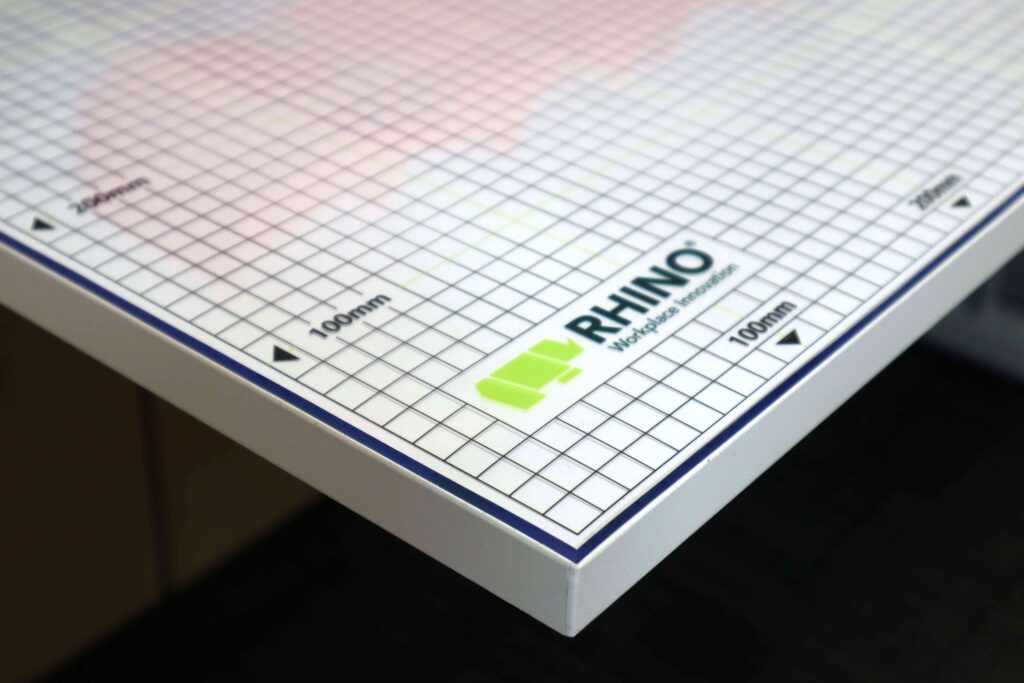

Uneven or damaged surfaces introduce variability into cutting, assembly and inspection tasks. High-quality, self-healing cutting mats and protective bench coverings help maintain consistent working conditions while protecting tools and benches.

Logical Flow of Materials

Materials should move logically from left to right (or vice versa), aligning with natural motion and reducing unnecessary handling.

Visual Clarity

Clear work zones, marked cutting areas and defined tool positions reduce decision-making time and improve accuracy.

A well-designed industrial workbench setup does not rely on operator adaptation, it supports correct work by default.

Process Improvement at Workstations Using 5S Methodology

The 5S methodology remains one of the most effective and scalable tools for eliminating micro-inefficiencies at the workbench level. For process engineers, 5S is not a housekeeping exercise, it is a structured framework for designing stable, repeatable and high-performance workstations.

When applied with intent, 5S becomes a foundation for sustained process improvement at workstations, enabling consistency, visibility and continuous optimisation.

Sort focuses on removing tools, fixtures and materials that are not required for the specific task. Excess items increase clutter, hide process issues, and force operators to waste time searching or working around unnecessary obstacles, reducing overall workbench efficiency in manufacturing.

Set in Order ensures that tools and materials are arranged based on frequency of use and process sequence. Frequently used items are placed within easy reach, while clearly defined work zones reduce unnecessary motion and improve flow, key objectives in process improvement at workstations.

Shine involves regularly cleaning workbenches and surfaces to maintain visibility and control. Clean, well-maintained surfaces make wear, damage and quality issues immediately apparent, allowing problems to be addressed before they affect productivity or output.

Standardise creates consistency across similar workstations by applying the same layout, tooling positions and working methods. This reduces variation between operators and shifts, shortens training time, and supports predictable, repeatable performance.

Sustain embeds 5S into daily operations through regular audits and operator ownership. Ongoing involvement ensures standards are maintained over time and supports continuous, Kaizen-driven workstation improvements rather than one-off fixes.

Tool, Storage & Utility Integration

Tool and storage integration is a major driver of workbench efficiency manufacturing. Poor integration forces operators to adapt; good integration eliminates wasted motion entirely.

Effective strategies include:

- Shadow boards for quick visual confirmation of tool availability

- Modular storage systems that adapt to changing processes

- Integrated power, air and data access at the bench

- Dedicated zones for cutting, measuring and assembly tasks

Workbench protection also plays a role here. Durable cutting and work surface mats prevent damage from repetitive cutting and tool use, reducing maintenance downtime and extending bench life.

For process engineers, these changes represent practical, measurable improvements rather than theoretical optimisation.

Kaizen Workstation Improvements in Practice

Kaizen is a continuous improvement approach focused on making small, incremental changes to processes, layouts and behaviours to improve efficiency, quality and safety over time. It is most effective when applied at the workstation level, where small changes produce immediate feedback.

Real-world Kaizen workstation improvements often include:

- Repositioning tools to reduce reach distance

- Introducing surface protection to stabilise cutting operations

- Standardising bench layouts across shifts or lines

- Adding visual guides or reference markings

These changes rarely require major capital investment. Instead, they rely on observation, experimentation and operator involvement.

In advanced manufacturing environments, continuous Kaizen workstation improvements help teams stay adaptable while maintaining consistency and control.

Measuring Impact and ROI

No improvement initiative is complete without measurement. Process engineers must be able to demonstrate the value of changes made at the workbench.

Key metrics include:

- Cycle time reduction

- Decrease in operator motion

- Reduction in rework or scrap

- Improved tool life and surface longevity

- Operator fatigue and injury reports

Even small gains — seconds saved per cycle — can translate into substantial annual savings. When improvements support workbench efficiency manufacturing, ROI often becomes evident within weeks rather than months.

Documenting these results also helps justify future investments in better work surfaces, tooling and workstation design.

Final Words

Micro-inefficiencies are rarely dramatic, but they are relentless. Left unaddressed, they quietly undermine productivity, quality and operator wellbeing.

For process engineers, improving workbench efficiency manufacturing is one of the most effective ways to support lean manufacturing objectives, reduce waste and create stable, repeatable processes. Through thoughtful industrial workbench setup, disciplined process improvement workstations, and ongoing Kaizen workstation improvements, small changes can deliver lasting results.

The most efficient workbenches are not the most complex, they are the ones that allow operators to focus entirely on value-adding work. Using high-quality, durable surfaces and tools, such as those offered by Rhino Cutting Mat, can help maintain precision, protect workbenches and support smoother workflows, making micro-inefficiency reduction easier and more effective.

FAQs

How do micro-inefficiencies differ from traditional production bottlenecks?

Micro-inefficiencies occur at the task and workstation level rather than across an entire production line. While bottlenecks limit overall throughput, micro-inefficiencies quietly reduce efficiency through repeated small losses such as extra hand movements, inconsistent surfaces or unnecessary adjustments during each cycle.

When should a process engineer prioritise workstation-level improvements?

Workbench-level improvements should be prioritised when overall equipment performance appears stable, yet productivity, consistency or operator fatigue issues persist. These symptoms often indicate hidden inefficiencies at individual workstations rather than system-wide constraints.

How can workbench efficiency improvements support automation readiness?

Standardised, efficient workbenches create predictable processes, which are essential for successful automation. Reducing variation in layout, tooling and surface conditions helps ensure that manual processes are stable before introducing semi-automated or automated solutions.

What role do work surfaces play in process stability?

Work surfaces directly affect precision, tool performance and repeatability. Inconsistent or damaged surfaces can introduce variation into cutting, measuring or assembly tasks, making it harder to maintain consistent quality and reliable cycle times.

How can process engineers justify small workstation investments to management?

Small workstation improvements can be justified by linking them to measurable outcomes such as reduced cycle time, lower rework rates, improved tool life and reduced operator fatigue. When these gains are scaled across shifts or production volumes, the return on investment becomes clear and data-driven.