How Custom Cutting Mats Transform Precision Tasks

Precision is the hallmark of quality craftsmanship, whether you’re a detailed hobbyist, a professional designer or a production specialist. Cutting tools and surfaces that don’t offer precision can introduce errors, wasted material and even injury. That’s why custom cutting mats are such a revelation. Coupled with Rhino’s intuitive Custom Size service, you can tailor your mat to your exact workspace dimensions, ensuring accuracy, safety and efficiency from the very first cut.

What Are Self‑Healing Cutting Mats and Why Do They Matter?

Self‑healing cutting mats are specially engineered surfaces designed to absorb cuts and then ‘heal’ back to a flat, usable surface. Typically constructed from layered PVC (or similar material), the mat splits under the blade’s pressure rather than slicing clean through. Once pressure is removed, the material naturally closes back, hiding the incision.

This clever design offers three standout advantages:

- Protection of work surfaces: Prevents damaging desks, benches or tabletops during cutting tasks.

- Preservation of blade sharpness: Unlike hard surfaces that dull blades quicker, the mat cushions and prolongs blade life.

- Consistent precision: Since grooves don’t develop, every cut remains sharp and accurate.

Looking for a reliable, all-round cutting solution? Explore our Medium Duty Cutting Mat, ideal for workstations that demand both durability and flexibility.

Precision and Safety: Their Impact on Productivity

Beyond durability, self-healing mats deliver precision and safety. Most feature printed gridlines, measurement guides and angle markings, helping you achieve straight cuts and accurate dimensions every time.

From Rhino’s own data:

- 68% improved preservation of work surfaces

- 77% reduction in hand injuries

- 50% lower tool replacement costs

These are not just stats but tangible improvements that enhance workplace safety, reduce costly errors and drive productivity.

Why Custom Size Cutting Mats Elevate the Experience

Standard mats often fall short, whether they’re too small, don’t align with your bench dimensions, or leave awkward gaps that hinder precision. This is particularly problematic in professional or high-volume environments, where every millimetre of space matters. Poorly fitting mats can create inefficiencies, pose safety risks and ultimately compromise the quality of your work.

Made-to-measure mats solve this elegantly, offering a host of practical advantages:

- Perfect fit: A mat that aligns precisely with your workbench not only looks professional but performs better. It stays flush with the edges, avoids shifting and supports a seamless workflow, especially important when using cutting guides, rulers or repeatable processes.

- No wasted space: With a custom fit, your entire workbench becomes a usable surface. This is essential for large-format projects (like signage, textiles or sheet cutting), where working off-mat introduces inconsistencies or damages tools and surfaces.

- Enhanced safety: Overhangs and misaligned edges often lead to unintended blade slips, material snags or even minor injuries. Custom mats eliminate these risks by sitting securely and predictably on the bench, providing confidence in every cut.

- Improved material handling: Larger or irregularly shaped materials no longer require awkward repositioning. A mat tailored to your workflow helps you move, trim and rotate materials with ease, reducing fatigue and boosting productivity.

- Aesthetic and functional integration: In customer-facing or collaborative environments, a clean, well-fitted mat demonstrates professionalism and attention to detail. It complements the bench rather than looking like an afterthought.

- Better tool preservation: With full surface coverage, you avoid cutting onto bare bench areas or overlapping multiple mats, both of which accelerate blade wear and damage worktops.

For professionals looking to pair their made-to-measure cutting mats with a durable setup, explore our custom metal workbench for industrial use. Combining bespoke cutting mats with heavy-duty workbenches ensures workstation safety compliance and maximises precision in demanding environments.

Rhino’s Custom Size service makes this process seamless: you simply enter your dimensions, and we manufacture a precision-cut mat to fit your bench, workstation or unique setup. Whether it’s for a compact craft desk or an industrial packing line, made-to-measure cutting mats ensure you get the most from your workspace, without compromise.

Craft with confidence. Our cutting mats for crafts and fabrics are perfect for textiles, quilting and precision fabric work.

The Long-Term Value of Investing in Quality Mats

A well-made cutting mat is a long‑term investment:

- Durability: Self‑healing surfaces resist wear, and many users report mats lasting for years.

- Blade savings: Reduced dulling means fewer blade replacements.

- Double-sided use: Flip the mat to extend its lifespan, especially beneficial for high-frequency tasks.

Choosing the Right Cutting Mat for Your Needs

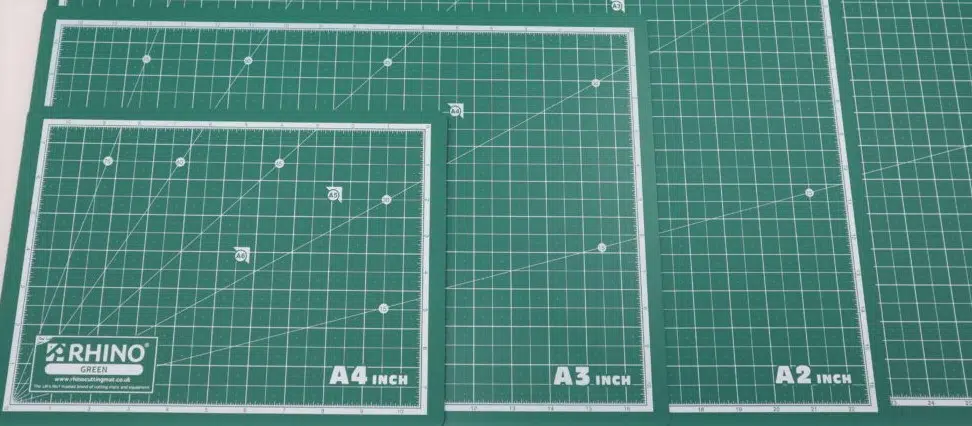

Size

Common formats range from A4 through A1, but with custom options, you’re no longer constrained by standard limitations. When selecting a size, consider both the nature of your projects and your available workspace. Oversizing slightly can offer flexibility, especially for rolling materials or larger-than-expected tasks. Similarly, matching mat size to specific stations (e.g. trimming, finishing, assembly) ensures each area is purpose-built.

Thickness

- ≈3 mm: Suited to light or occasional use, such as crafting, hobby projects or low-volume prototyping. These are often more portable and cost-effective.

- ≈5 mm+: Ideal for heavy-duty, repeated cutting tasks in workshops, manufacturing or packaging environments. These offer better resistance to deep cuts and minimise deformation over time.

If your work involves frequent, forceful cutting, such as with rotary tools, scalpels or guillotines, a thicker mat will better absorb pressure and preserve both the surface and your tools.

Surface Features

- Gridlines and angle guides: These visual cues ensure clean, repeatable cuts and help align materials accurately, especially useful for textiles, print layouts or signage.

- Non-slip backing and matte finish: A stable mat surface prevents unwanted movement, while the matte finish reduces glare under overhead lighting, reducing eye strain during extended tasks.

- Anti‑static options: Ideal in electronics assembly or applications sensitive to electrostatic discharge (ESD). These mats help dissipate ESD that could otherwise damage components.

Materials

- Self-healing PVC: Provides the best balance of durability, affordability and flexibility. Resistant to repeated use and suitable across most sectors.

- Glass mats: Provide a rigid, ultra-flat surface ideal for photographic work or precision craft, but they dull blades faster and are fragile, making them less suitable for high-frequency use.

- Non-self-healing plastics: Budget-friendly, but they wear more quickly and develop permanent grooves, which can lead to jagged cuts and faster blade deterioration.

For most users, especially in commercial or industrial settings, self-healing PVC mats are the gold standard, combining longevity, user safety and excellent cutting consistency across a range of applications.

Achieve straighter, more accurate cuts every time with our cutting mats with printed grids, a must-have for layout alignment and repeatable projects.

Care Tips for Lasting Mat Performance

Proper care ensures your cutting mat remains in top condition for years. By following a few simple maintenance practices, you can extend its life, maintain its self-healing properties and preserve surface accuracy.

- Store flat and out of direct sunlight: Mats should always be stored flat, never rolled or folded, as this can cause permanent warping. Avoid leaving your mat near radiators, windows or other heat sources, as prolonged exposure to heat or UV can cause the material to become brittle or discoloured over time. If you must transport your mat, ensure it lies flat again as soon as possible.

- Clean gently with mild soap and water: Use a soft cloth and lukewarm water to remove dust, ink, or adhesive residue. Avoid harsh cleaning agents or solvents, as these can degrade the surface and reduce the mat’s self-healing effectiveness. If glue builds up from repetitive tasks, a small amount of white vinegar or adhesive remover (used sparingly) may help, always test on an edge first.

- Use sharp blades and rotate cutting positions: A dull blade can tear rather than slice the mat surface, weakening its healing properties. Always use a clean, sharp blade and cut at a consistent 90° angle. To distribute wear evenly, vary your cutting positions and, if the mat is double-sided, flip it regularly. This simple habit helps prevent deep grooves forming in high-use areas.

- Avoid prolonged weight or pressure: Heavy tools or equipment left on the mat can cause surface impressions or warping over time. Clear the mat after use to maintain its integrity.

If your workspace includes heavy-duty or adjustable benches, proper maintenance is just as important as mat care. Our guide on how to extend the lifespan of your workbench offers practical tips to keep your setup in peak condition, ensuring your bespoke cutting mats for specialist projects and work surfaces perform flawlessly together.

Why Rhino’s Custom Size Service Makes It Easy

Rhino’s Custom Size service delivers made-to-measure mats built precisely to your specifications, no guesswork. This ensures:

- Perfect alignment with your workspace.

- Enhanced precision, safety and workflow.

- Eco-friendly sourcing: longer-lasting mats, recyclable materials, and reduced waste align with Rhino’s sustainability mission.

Ready to elevate your precision work? Use the Custom Size feature now to get tailored, high-performance mats built for your unique needs.

Need extra space? Discover our large self-healing cutting mats for bigger projects and superior surface protection.

Custom cutting mats transform workspace efficiency by delivering:

- Precise, consistent cuts

- Enhanced safety and surface protection

- Long-lasting performance and blade longevity

- Perfect fit for seamless integration

With Rhino’s Custom Size service, achieving this level of precision has never been simpler, or smarter. Discover how tailored cutting mats can elevate your craftsmanship and explore the Custom Size feature today.