This high-performance cutting mat has a number of key characteristics that make it ideally suited for sign makers, especially those needing to replace the surface in a flatbed laminator or graphics mounting table.

Smooth Surface

The Supaseal surface is completely smooth, which is really important for lamination work. When pressure is applied to the graphics during the lamination process, a roughened surface can cause problems – the ideal surface is completely flat. This also helps when cleaning up, for instance, if you need to remove some glue residue or have been working with a dusty product.

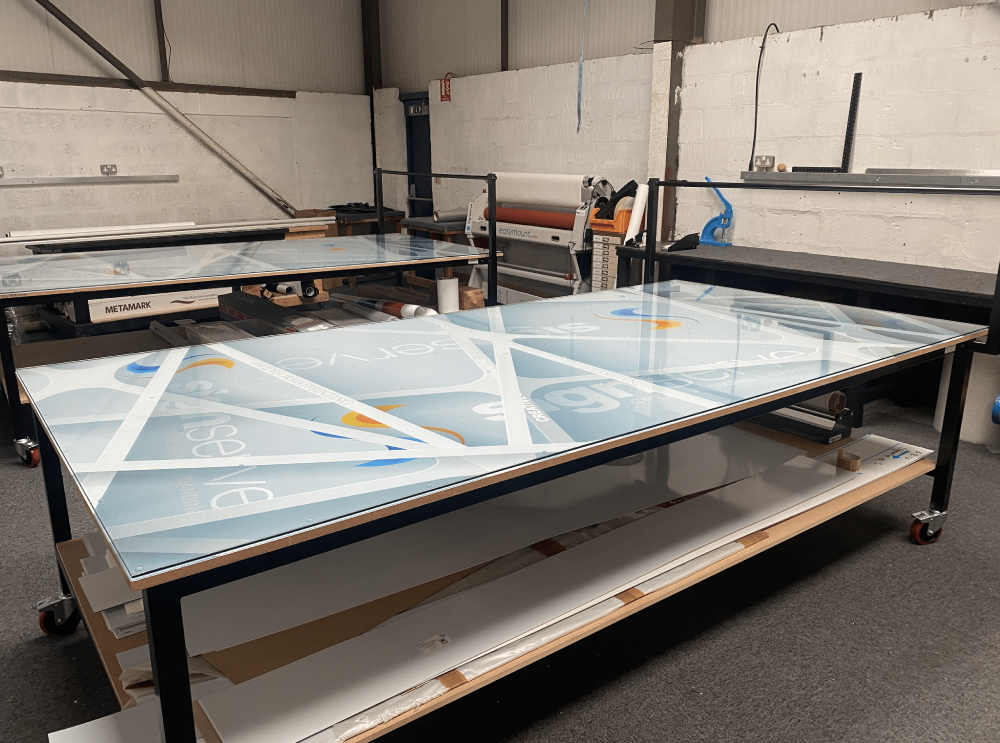

Large Sizes

One of the reasons why Supaseal is so important to sign makers is the range of sizes in which it comes. Cut-to-size, Superseal can be supplied in single pieces up a massive 2.2m x 20m. Having a cutting mat in one single piece is critical for flatbed applicators as joints in the cutting surface can cause problems. This is the same for graphic mounting tables. Well-known laminator brands such as Kala and Rollsroller offer flatbeds over 2m wide for use with very large graphics. The 2.2m wide Supaseal is big enough to cope with these and is supplied in the exact dimensions required.

Optical Clarity

The Supaseal is also one of the best cutting mats for optical clarity and lack of blemishes. This means it works really well with illuminated tables. An illuminated work surface makes quality control much easier, as faults and blemishes in the graphics stand out sharply.

Harder Surface

The mat itself is slightly harder than many other cutting mats, which is an advantage for lamination tables. If the surface is too soft, the graphic will deform under pressure, which can lead to curling and wrinkles. However, the surface does need to have some ‘give’, to equalise support under different thicknesses of material, so Supaseal is designed to have that optimum level of firmness. Although the surface of Supaseal is harder than many mats, it is actually very flexible and pliable, making it easy to roll up if you need it out of the way temporarily. As with all mats, we recommend storing flat if storing for a long period.

Double Sided

The Supaseal cutting mat is double-sided, meaning if one side becomes damaged, you can simply turn it over and use the other side. The way the product is made means that the properties of both sides are identical, doubling the life of the product in most cases.

Self Healing

Finally, the Supaseal has excellent self-healing properties. When using it to trim up graphics, not only will the blade slide smoothly and true, but it stays sharper for longer, and most cut lines just disappear. Self-healing cutting mats do not shred the surface or leave score marks, this means the surface can be kept immaculately clean, even after repeated cuts. This is very important for flatbed applicator tables, as tiny shreds of cutting surface or offcuts from weeding vinyl can find their way beneath the surface and spoil lamination, causing tiny bubbles.