What is a Self-Healing Cutting Mat and Why Do You Need One?

Self-Healing Cutting Mat: Why You Need One for Precision and Durability A self-healing cutting mat is an essential tool for anyone working with precision cutting, whether for crafting, sewing, model-making or professional design. Unlike standard cutting boards, these mats are made from flexible, durable materials that allow the surface to close up after each cut, […]

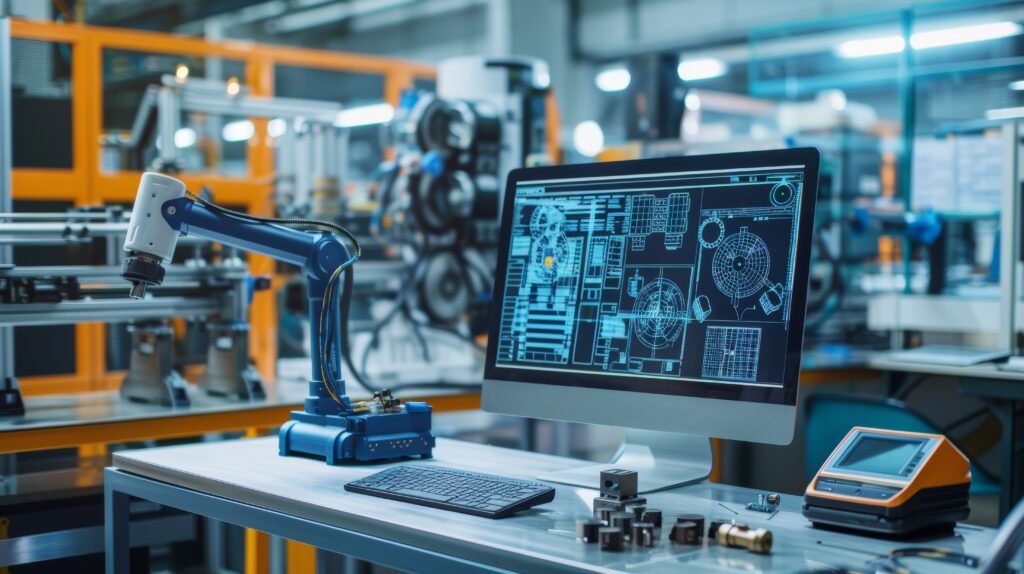

Cutting and Working with Composites in Manufacturing: High Performance Cutting Mats

The UK’s advanced manufacturing sector thrives on innovation. Composite materials, known for their light weight, strength and versatility, are playing an increasingly vital role in this landscape. From aerospace to automotive and clean energy, composites are changing the game. However, working with composites presents unique challenges. Cutting these materials requires precision and cleanliness, especially in […]

Cutting Mat User Survey Reveals Huge Safety Benefits

Recent research conducted on the efficacy of Rhino cutting boards has unveiled a significant increase in reported safety, particularly for users of hand-held cutting knives.

Improving Air Purity In Cleanrooms

Cleanrooms require meticulous control of air quality to maintain a sterile and dust-free environment. The initial cleanroom design and installation is the first thing, but the air quality is also dependent on proper daily operational practice and good maintenance.

What’s The Best Workbench Protection?

Keeping your bench top in great condition is essential for safe, effective and efficient workmanship. As any maker, engineer or mechanic knows, the typical worktop gets scratched, dented and contaminated with glue, soldering drips and dirt building up in knife marks all too soon. Many different materials have been developed as more durable alternatives to […]

Cutting Mats and Surface Protection in Composite Manufacturing – The What, Where, and Why

First, What Are Composite Materials? Composites are materials made from more than one material, which unlike alloy or paint, are ‘fused’ into one piece without being mixed. The advantage of composites is that they result in the best of each raw material. The matrix is often made from ‘opposites’ such as a tensile-resistant fibre and […]

Work Surfaces In High-Performance, Advanced Material Manufacturing

Today’s high-performance teams in the auto and aviation industries all have one thing in common – a relentless commitment to optimum performance in every area. In the highly competitive world of performance motorsports, crossing that finish line first or breaking a new record by milliseconds comes from the disciplined approach to every detail of testing, […]

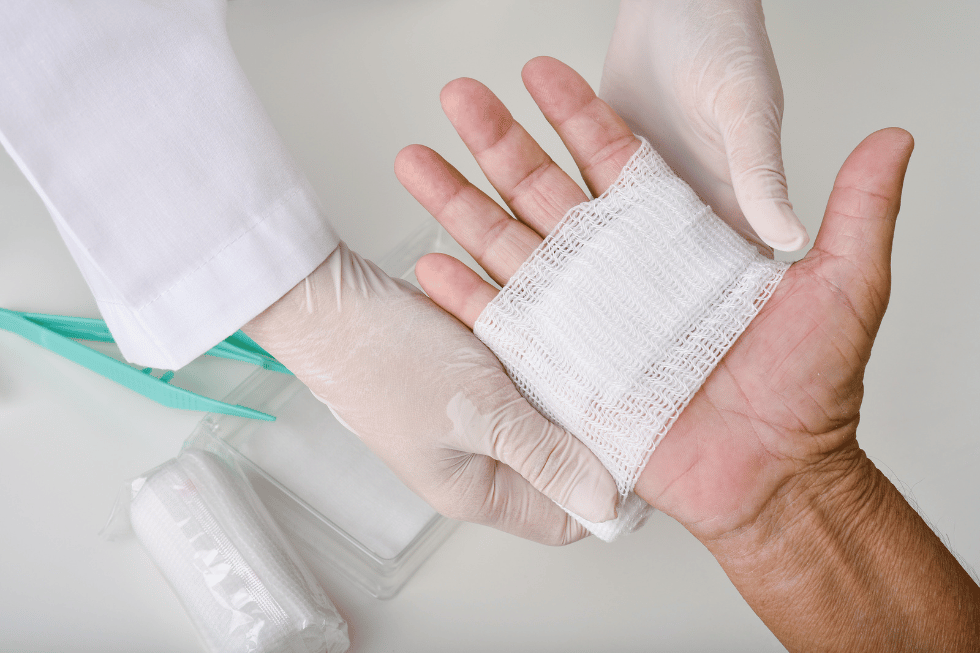

Cutting Mats: Safe Use of Knives In The Workplace

Cutting Out Hand Injury In a previous blog post about keeping knives sharp by using a cutting mat, the subject of hand knife safety was mentioned. With hand knife safety being such an important topic, we thought it deserves its own dedicated article. “Hand knife injuries typically account for between 25-50% of all lost time […]

What Makes A Perfect Surface For Cleanroom Fit-Out?

Whilst some parameters of a cleanroom are dependent on the level and type of contamination risk, what they all have in common is a need to control the concentration and maximum size of dust particles to a specified level. This means that the ideal cleanroom surface material should be: Smooth; textured surfaces are more difficult to clean […]

Importance of Blade Sharpness in Precision Manufacturing

Keeping cutting knives sharp is of utmost importance in any factory setting, particularly when there is a need for accurately cutting delicate substrates and materials by hand. Scalpel blades are used in many manufacturing processes, where precise hand cutting is preferred over machine cutting. Delicate textiles, carbon fibre cloth, leathers, specialist materials where automation set-up errors can quickly […]